In hot and humid climates, the insulation materials of electrical equipment face severe challenges, and DDP has become an ideal choice for such environments with its unique material properties and exquisite structural design.

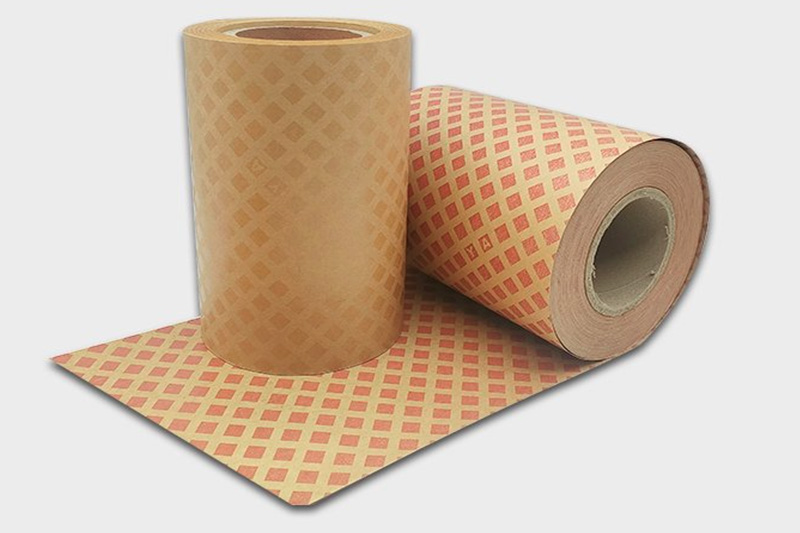

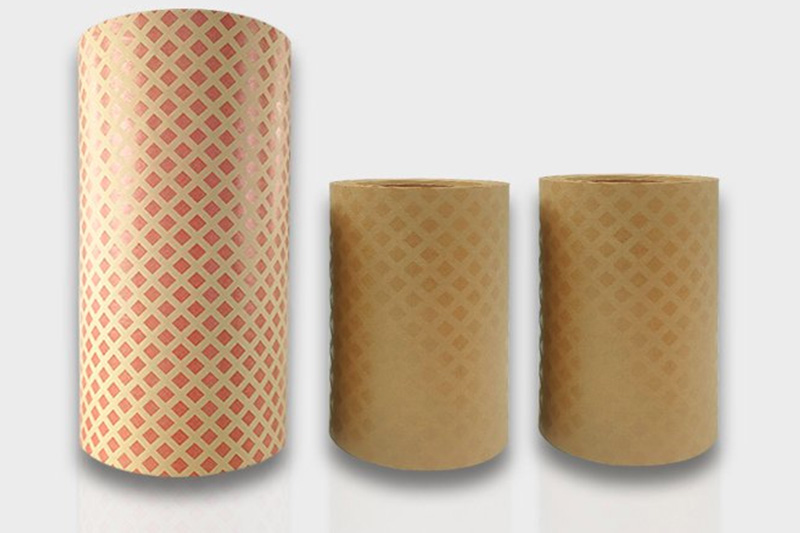

DDP forms a unique dot structure by coating special modified epoxy resin on electrical insulation paper in a diamond shape. This design not only ensures the insulation performance, but also allows the transformer oil to fully penetrate the material, while promoting the discharge of gas in the insulation material. In high temperature and high humidity environments, the diamond-shaped structure can effectively avoid corona and partial discharge caused by gas retention, ensuring the long-term reliability of the insulation structure.

During the drying process of the transformer coil, the coating layer of DDP will melt at a specific temperature and produce adhesion, and then the layers of the winding will be firmly bonded into a whole through the curing process. This bonding strength is sufficient to resist the displacement of the layers of the winding during a short circuit and ensure the mechanical stability of the insulation structure. At the same time, the dot coating only penetrates into the insulating paper in a small amount during the curing process, which further enhances the material’s resistance to moisture and heat aging.

DDP insulation material has excellent heat resistance. Its coating layer can remain stable at high temperatures and can maintain good electrical and mechanical properties in high temperature environments. This feature allows DDP to work reliably in hot climates and will not be damaged by excessive temperatures.

DDP insulation paper has good moisture resistance. Its coating layer can effectively prevent moisture penetration and maintain its insulation performance even in humid environments. This feature allows DDP paper to provide reliable electrical isolation in humid climates and prevent electrical failures caused by moisture.

In addition, DDP also has excellent mechanical properties and chemical stability. Its coating layer can maintain good insulation effect in high temperature, high humidity or highly corrosive environments, further enhancing its applicability in hot and humid climates.

DDP has been widely used in oil-immersed power transformers. Its diamond-shaped structure effectively promotes the immersion of transformer oil and the discharge of gas, avoiding corona and partial discharge. Practical applications show that this material can significantly improve the operating reliability and life of the transformer.

DDP insulation materials also perform well in distribution transformers. Its excellent heat resistance and moisture resistance enable it to adapt to long-term operation requirements in high temperature and high humidity environments, ensuring stable power supply of the distribution system.

DDP insulation paper, with its scientific structural design and excellent performance, has built a solid safety line for the operation of electrical equipment in hot and humid climates. Against the background of increasingly complex and changeable global climate environments, the application of DDP not only ensures the stable operation of the power system, but also provides new solutions for the reliability of electrical equipment in extreme environments. Its broad application prospects and continuous technological innovation potential are worthy of continuous attention and in-depth exploration by the industry.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……