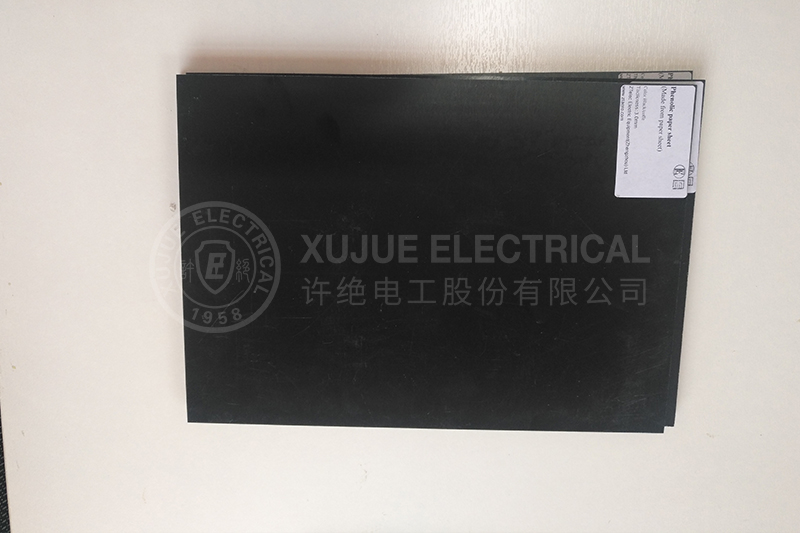

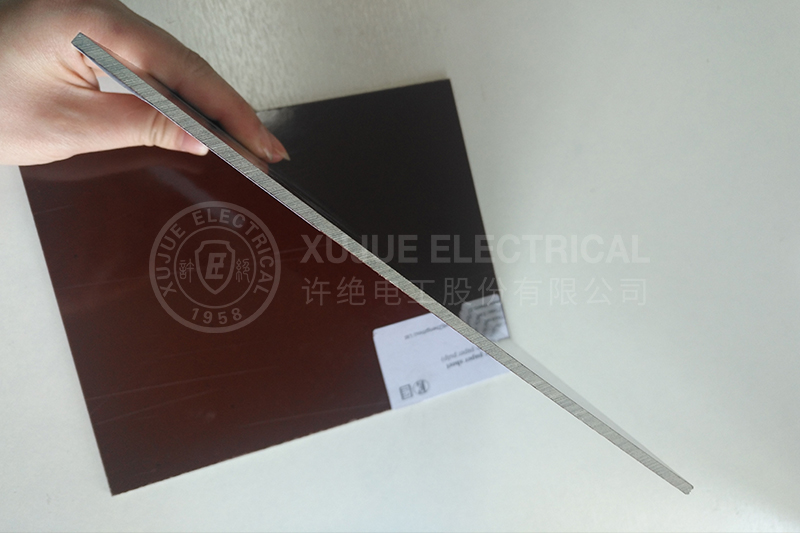

Bakelite, also known as phenolic laminated paperboard, is a very sophisticated manufacturing process. It is made of high-quality bleached wood building paper and cotton linter paper as reinforcement materials, and phenolic resin made from high-purity, fully synthetic petrochemical raw materials as adhesive. This bakelite plate not only has excellent physical properties, but also plays a very critical role in the field of electronic production. It is non-absorbent and non-conductive, and it is also resistant to high temperatures and high strength, making it an ideal choice for the manufacture of electrical products. Whether it is making fixtures or performing performance tests, bakelite plate can show excellent performance. So why is bakelite plate the perfect electrical insulation application? Let’s analyze it in detail.

Bakelite has extremely high resistivity, which can effectively prevent the passage of current, thereby ensuring that electrical equipment and lines can operate safely. Moreover, even under extreme conditions such as high voltage and high frequency, bakelite plate can still maintain stable insulation performance and is not prone to breakdown or leakage. It is precisely because of these excellent insulating properties that bakelite has become an indispensable insulating material in the field of electronics and electricity, and is widely used in the production of key components such as insulating switches and variable resistors.

The bakelite is made of phenolic resin and high-quality reinforcing materials such as bleached wood building paper and cotton linter paper, so it has high mechanical strength and hardness. This enables the bakelite to withstand greater mechanical stress and impact, and is not easily deformed or damaged during use, ensuring long-term stability under complex working conditions. It is also because of this good mechanical strength that bakelite is suitable for electrical equipment and structural parts that need to withstand certain external forces.

The heat resistance of bakelite is excellent, and it can maintain stable physical and chemical properties in high temperature environment. Under high temperature conditions, bakelite will not easily soften, deform or decompose, thus ensuring long-term reliability in high temperature working environment. With this heat resistance, bakelite is very suitable for electrical equipment and industrial application scenarios that need to withstand high temperatures.

The bakelite has good resistance to chemicals such as acids, alkalis, and salts, and is not easily corroded or eroded. Therefore, it can maintain stable performance in harsh chemical environments and effectively extend its service life. Based on this chemical stability, bakelite performs well in electrical equipment and structural parts applications in industries such as chemical and petroleum.

The mechanical processing performance of bakelite plate is good, and it is relatively easy to perform processing operations such as cutting, drilling, and milling. Moreover, it can be processed into various shapes and sizes according to specific needs, which can meet the diverse needs of different application scenarios. This excellent processing adaptability gives bakelite plate a wide range of application prospects in electronics, machinery and other fields.

Bakelite plate is an ideal choice for electrical insulation applications due to its excellent insulation performance, excellent mechanical strength, good heat resistance, chemical stability and processing adaptability. With the continuous advancement of science and technology, various industries have increasingly stringent requirements for material performance. Bakelite plate will also emerge in more emerging fields with its own advantages and continue to protect electrical safety and industrial production.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……