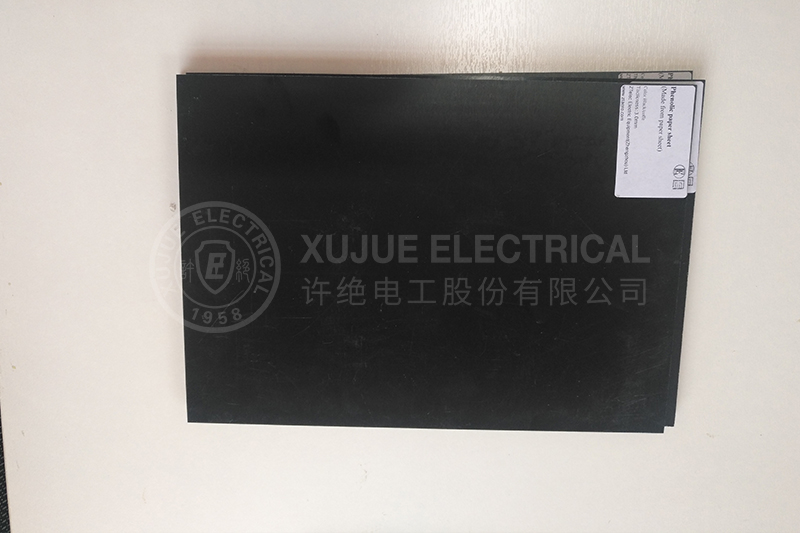

As a critical material in the field of electrical engineering, Bakelite plate is widely recognized for its performance and applications. Below, we will explore its key characteristics, relevant standards, and practical uses in detail.

One of the primary reasons Bakelite plays a vital role in electrical equipment is its outstanding electrical insulation capability, which effectively blocks current conduction. During the operation of electrical devices and electronic instruments, Bakelite serves as a crucial insulating material. With its superior insulation properties, it forms a reliable barrier that ensures equipment stability and user safety. For example, in components such as circuit boards and distribution boxes, Bakelite plate accurately isolates electrical current, effectively preventing leakage risks.

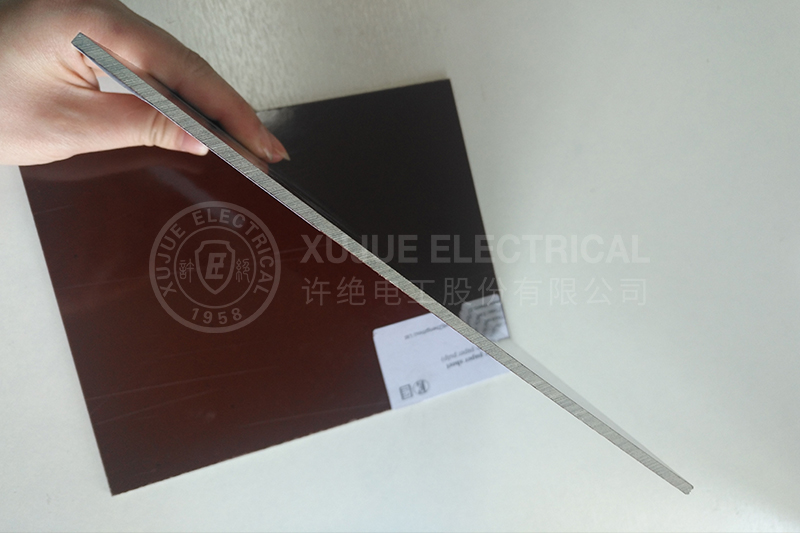

In addition to excellent insulation, Bakelite possesses considerable mechanical strength, making it capable of withstanding a certain degree of impact and pressure. This gives it strong resistance to damage. Owing to this property, Bakelite is often used in the production of load-bearing components, such as insulating structural parts of motors and mechanical handles. Even under vibration or external force, components made from Bakelite can maintain their shape and ensure stable performance.

Bakelite sheet not only performs well in electrical and mechanical applications but also shows excellent resistance to a variety of chemicals, including acids and alkalis. This chemical durability allows it to be widely used in the chemical industry and harsh chemical environments. For instance, in chemical laboratories, workbenches and containers for storing chemical reagents are often made from Bakelite, effectively extending their service life.

Bakelite plate can maintain stable performance even in high-temperature environments. It is not prone to deformation or loss of its original properties due to elevated temperatures. Generally, Bakelite can operate continuously within relatively high temperature ranges, making it suitable for applications with specific heat resistance requirements, such as heat-dissipating components in electronic devices.

In addition, Bakelite is easy to process using various mechanical operations such as cutting, drilling, and milling. Thanks to its excellent machinability, it can be fabricated into complex shapes and sizes according to different requirements, fully meeting the diverse needs of various industries. Whether it’s a simple flat component or a complex custom-shaped part, Bakelite can be machined accordingly.

To ensure quality and regulate usage, the production and application of Bakelite must comply with a series of international and industry standards.

Key international standards include:

· IEC 60893: A standard for industrial rigid laminated sheets of insulating materials.

· ASTM D709: A U.S. standard that specifies the performance of phenolic laminated sheets.

In China, relevant standards include:

· GB/T 1303: Specifies the requirements for rigid laminated sheets based on thermosetting resins for electrical purposes.

· GB/T 5130: A standard specifically for phenolic laminated paper sheets.

In addition to the above standards, Bakelite must also meet other certifications such as:

· UL Certification (e.g., UL 94 flame retardant rating)

· RoHS compliance (Restriction of Hazardous Substances for environmental protection)

Thanks to its multiple outstanding properties, Bakelite is widely used across various fields.

In the insulation structures of electrical devices such as motors, transformers, and switchgear, Bakelite is commonly used to produce insulating pads, partitions, brackets, and more. These components effectively isolate electrical circuits and prevent leakage, thereby ensuring the safe and stable operation of the equipment. Similarly, in high- and low-voltage distribution boxes within power distribution systems, Bakelite sheet serves as a reliable insulating part, enhancing the safety and dependability of electrical connections.

In the field of electronic component manufacturing, Bakelite is an ideal material for producing insulated switches and variable resistors, thanks to its excellent insulating properties. Its use helps improve the stability and durability of electronic products. Additionally, in the production of printed circuit boards (PCBs), Bakelite is often used as a drill backing board, providing stable support and preventing damage to the PCB during drilling.

In power systems, Bakelite plate is applied in components such as insulators and switchgear, playing a critical role in insulation and isolation to ensure the stable operation of power equipment.

Due to its high mechanical strength and wear resistance, Bakelite is frequently used in the manufacturing of mechanical molds and production jigs. For example, in ICT (In-Circuit Testing) and ITE (Information Technology Equipment) jigs, Bakelite plate is used to fabricate insulating components, helping to ensure machining precision and operational stability.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……