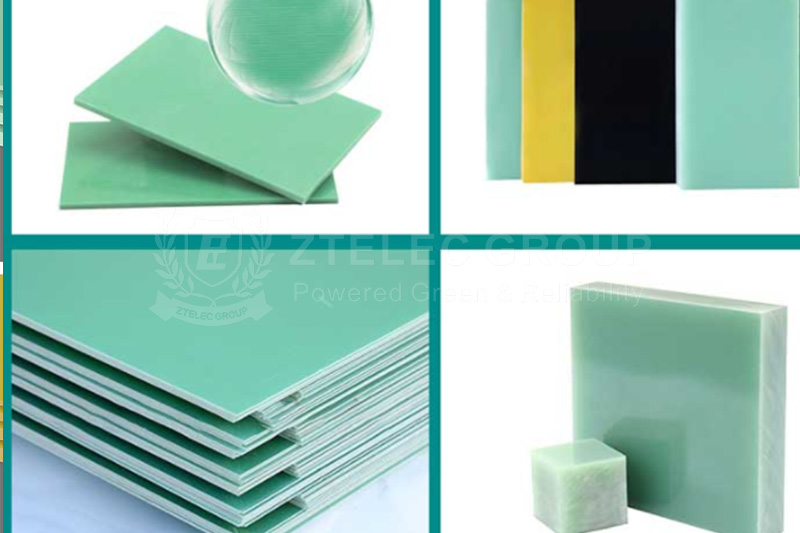

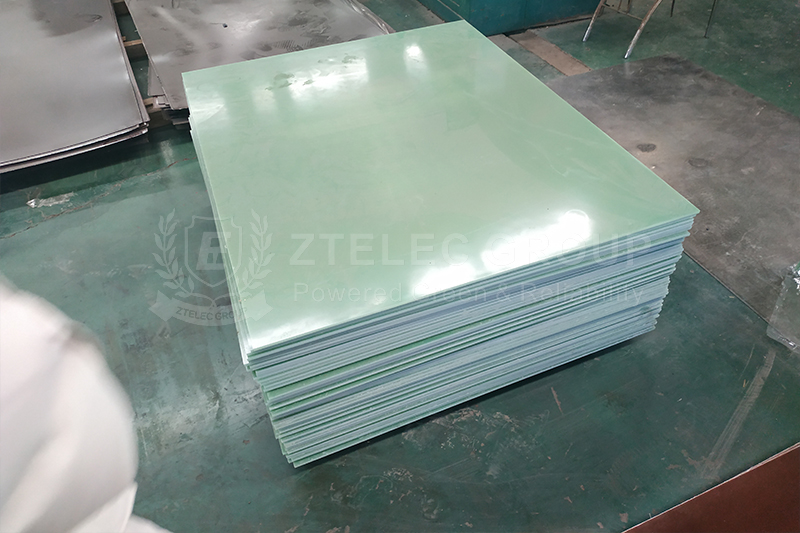

FR4 materials have high mechanical strength and good toughness. It is not easy to break or deform during drilling and milling processes in the manufacture of multi-layer circuit boards, ensuring manufacturing accuracy. Its impact resistance can also withstand collision and vibration during transportation and use, ensuring the stability of the equipment.

FR4 materials have excellent insulation properties, which can effectively prevent current leakage, reduce signal transmission loss and interference. In high-frequency circuits such as communications and radars, it can reduce signal attenuation and ensure stable operation of the circuit.

Under normal operating temperature, FR4 materials have stable performance and will not soften and decompose. When high-temperature is generated during the operation of high-power equipment, it can ensure the normal operation of the circuit board and extend the life of the equipment. At the same time, it meets the flame retardant standards, can self-extinguish when encountering fire, and improve safety.

FR4 materials can withstand common acid, alkali, salt solutions and organic solvents. During the use of electronic equipment, they can prevent the substrate from being corroded by detergents, pollutants, etc., and maintain the performance and appearance of the circuit board. In complex industrial environments, it can also ensure the long-term stable operation of equipment.

FR4 material supports mechanical processing such as drilling and milling, as well as chemical processing such as etching and electroplating. It has high processing accuracy and can meet the manufacturing needs of different circuit boards. It is suitable for large-scale production, which can improve efficiency and reduce costs.

FR4 material is the most commonly used substrate material in printed circuit board manufacturing. Whether it is a single-sided board, a double-sided board, or a multi-layer board, it can meet the design and manufacturing requirements. In a single-sided board, the FR4 substrate provides support and electrical connection for electronic components; double-sided boards and multi-layer boards use FR4 materials to connect multi-layer circuits through a lamination process to achieve complex functions.

FR4 materials can be used to manufacture packaging shells and bases for electronic components. In integrated circuit packaging, the FR4 shell can protect the chip and provide electrical connections and heat dissipation channels. For high-power electronic components such as power transistors and rectifiers, the FR4 base can withstand heat and mechanical stress to ensure stable operation of the components. In the field of automotive electronics, components encapsulated with FR4 materials can adapt to harsh environments such as high temperature and vibration inside the car, ensuring the reliable operation of automotive electronic systems.

In electronic equipment, FR4 materials are often made into insulating brackets, partitions, etc. It can isolate circuits or components with different potentials to prevent short circuits and leakage. At the same time, its mechanical strength can provide stable support for electronic components and ensure the stability of the equipment structure. For example, in power supply equipment, FR4 insulating brackets are used to support components such as transformers and inductors to prevent them from displacement or collision during operation.

In the field of consumer electronics, FR4 materials are widely used in products such as smartphones, tablets, laptops, and smart wearable devices. As consumer electronic products develop towards thinness and high performance, the requirements for circuit boards are getting higher and higher. FR4 materials meet the needs of high-density wiring and multi-layer board manufacturing with their electrical, mechanical and processing performance advantages.

Communications equipment has high requirements for circuit board performance, and needs to have characteristics such as high-speed signal transmission, low loss, and high reliability. FR4 materials are used in base station equipment, routers, switches, optical communication equipment, etc. Entering the 5G communication era, the requirements for circuit board dielectric properties and signal integrity are more stringent. High-performance FR4 materials meet the needs of 5G communication equipment by optimizing formulas and processes. In 5G base stations, circuit boards made of FR4 materials achieve high-speed data transmission and low-latency communication, ensuring the efficient operation of 5G networks.

As the degree of automotive electronics increases, the demand for circuit boards in automotive electronic systems continues to increase. FR4 materials are used in engine control systems, body control systems, safety systems, infotainment systems, etc. The working environment of automobiles is complex, and has many problems such as high temperature, vibration, humidity, and chemical corrosion. The heat resistance, mechanical strength, chemical stability, and flame resistance of FR4 materials meet the special requirements of automotive electronic systems. In the automotive engine control unit, FR4 circuit boards can work stably at high temperatures to ensure engine operation; in the airbag system, FR4 materials ensure that the airbags pop out in time to protect the safety of passengers.

Industrial control equipment needs to operate stably for a long time in harsh industrial environments, and has extremely high requirements for the reliability and stability of circuit boards. FR4 materials are used in programmable logic controllers, inverters, servo drives, industrial sensors and other equipment. Its good mechanical, electrical and chemical corrosion resistance can adapt to the vibration, dust, humidity, chemical substances and other environments of industrial sites. In industrial automation production lines, programmable logic controllers made of FR4 circuit boards can accurately control the production process to ensure efficient and stable production; in inverters, FR4 materials can withstand large current and high voltage shocks to ensure reliable operation of inverters.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……