In the field of electronic circuit manufacturing, copper foil is the core conductive material. All kinds of electronic components such as printed circuit boards (PCBs) and flexible circuit boards (FPCs) cannot do without copper foil. The copper foil core tube, a seemingly ordinary accessory, plays an irreplaceable role in the storage, transportation and processing of copper foil. Its performance and quality directly affect the use of copper foil, and are more related to the final quality of electronic circuit manufacturing. Next, let’s analyze the specific role of the copper foil core tube in depth.

Copper foil is soft and ductile. Without effective support and fixation, it is easy to wrinkle, deform, or even break. The copper foil core tube provides a stable support structure, allowing the copper foil to be tightly and neatly wound on it. Whether it is stored in the production workshop or transported over long distances, the tube can ensure that the copper foil maintains a stable winding state. In this way, it can effectively avoid problems such as external force extrusion and collision that cause the quality of copper foil to deteriorate.

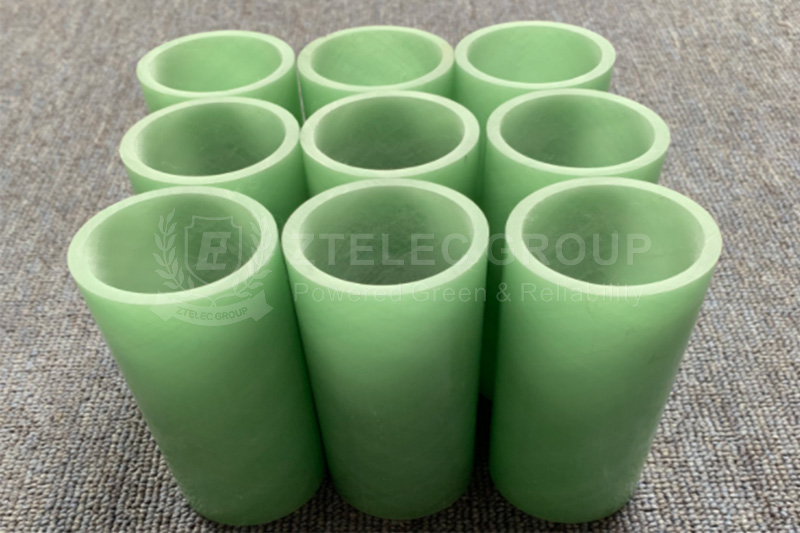

The copper foil produced by large copper foil manufacturers has a large roll diameter and can weigh hundreds of kilograms or even more. Without the support of the FRP tube, the copper foil will quickly lose its regular shape under its own gravity and external pressure, and the surface will become uneven, affecting its subsequent use in electronic circuit manufacturing. The tube, with its excellent mechanical strength and rigidity, can withstand the weight and external pressure of the copper foil, maintain the stability of the copper foil roll, and create conditions for subsequent processing and use.

The integrity and cleanliness of the copper foil surface are crucial to the manufacture of electronic circuits. Even slight scratches, stains, or oxidation may affect the conductivity of the copper foil, leading to short circuits, open circuits and other faults in electronic circuits. Copper foil core tubes play a key role in protecting the surface of copper foil.

On the one hand, the surface of the tube has been specially treated to be very smooth and flat. During the winding and unwinding of the copper foil, there is little friction between it and the copper foil, which can effectively avoid scratches. On the other hand, some high-performance copper foil core tubes also have moisture-proof and oxidation-proof functions. They can isolate the outside moisture and oxygen from contacting the copper foil, slow down the oxidation rate of the copper foil, keep the surface clean and the performance stable.

In an environment with high humidity, copper foil is easily oxidized when it is directly exposed, and a copper oxide film will form on the surface, reducing the conductivity. The use of moisture-proof core tubes can create a relatively dry storage environment for copper foil, extend the shelf life, and ensure that it plays a normal role in the manufacture of electronic circuits.

In the production process of electronic circuit manufacturing, copper foil core tubes also play an important auxiliary role. Modern electronic circuit manufacturing equipment is closely linked to the installation and use of copper foil rolls. The specifications and characteristics of the tubes directly affect whether the production process is smooth.

The inner and outer diameters of the core tubes are specially designed according to the requirements of the production equipment. Different electronic circuit manufacturing equipment has specific standards for the installation dimensions of copper foil rolls. The FRP core tubes with adapted sizes can quickly and accurately install and remove the copper foil rolls on the equipment, reduce equipment downtime, and improve production efficiency.

In addition, the material and weight of the copper foil core tube will also affect the copper foil feeding process. The light-weight and high-strength tubes can make the copper foil feeding smoother. In high-precision electronic circuit manufacturing processes such as FPC, the copper foil feeding accuracy is extremely high. At this time, high-quality copper foil core tubes can cooperate with the feeding equipment to accurately transport the copper foil to the specified position. This will ensure the accuracy of circuit graphics production and improve the product qualification rate.

From the perspective of enterprise management and logistics transportation, copper foil core tubes are also of great significance. Copper foil core tubes with unified specifications and standards facilitate enterprises to classify and manage copper foil and take inventory. Enterprises can quickly and accurately identify copper foils of different batches and specifications through the model, size and other information of the tubes, thereby improving warehouse management efficiency.

During transportation, copper foil core tubes can make the copper foil rolls more regular and easy to load and fix. Reasonably designed core tubes can make full use of the space of transportation tools, improve transportation efficiency and reduce transportation costs. Moreover, because the tubes can protect the copper foil, the loss during transportation is reduced, further reducing the production costs of enterprises.

Although copper foil core tubes are only small components in electronic circuit manufacturing, they play an important role in support and fixation, surface protection, auxiliary production, and optimized management and transportation. With the continuous development of electronic circuit manufacturing technology, the performance and quality requirements of copper foil core tubes will become higher and higher.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……