In the field of motor design and manufacturing, the choice of insulation materials directly determines the performance, lifespan, and reliability of the motor. With technological advancements, NHN and NMN composite insulation materials have become a core component of modern high-efficiency motor insulation systems. This article will delve into the application scenarios and technological advantages of NHN/NMN composite insulation in motors, helping you understand why this material has become a new industry standard.

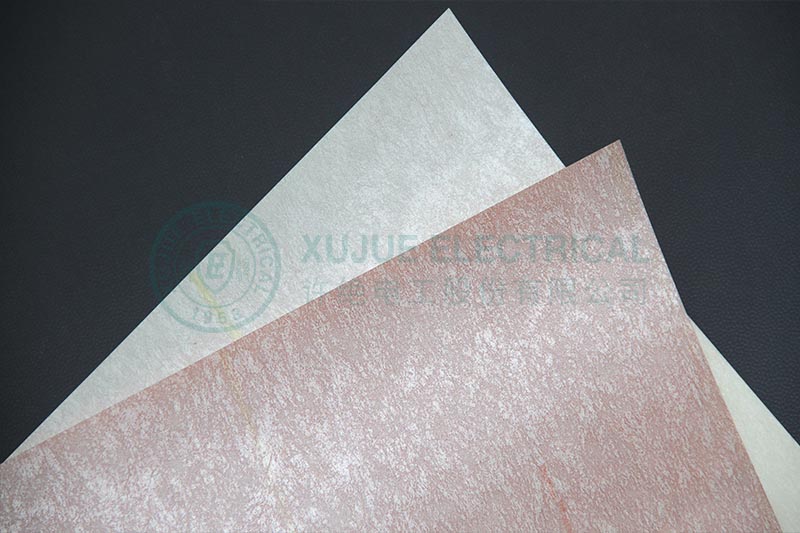

NHN and NMN are both multilayer composite motor insulation materials, typically composed of the following structures:

NHN Structure: Nomex + Polyimide film + Nomex

NMN Structure: Nomex + Polyester film + Nomex

The two materials are composited using a high-temperature resistant adhesive. They possess both the heat resistance and mechanical strength of Nomex paper, and the dielectric properties and flexibility of polyester film.

NHN/NMN is commonly used as the main insulation in stator slots, effectively isolating the windings from the core and preventing partial discharge and electrical breakdown. It is suitable for medium- and high-voltage motors operating under high loads.

Using NHN/NMN composite insulation between phases can improve the overall insulation level and reduce the risk of short circuits caused by vibration or thermal aging.

High-voltage or variable-frequency motors experience higher turn-to-turn voltage stress. NHN/NMN possesses stable dielectric strength and heat resistance, effectively delaying insulation aging.

NHN/NMN is available in a full range of specifications and is easy to process. It is widely used in motor overhaul, refurbishment, and upgrade projects to improve the insulation level and reliability of older motors.

High dielectric strength: The typical breakdown voltage of NHN/NMN material is 15-30kV/mm.

Low dielectric loss: Reduces energy loss and improves motor efficiency.

Corona resistance: Suitable for use in variable frequency motors, and can resist partial discharge caused by high-frequency pulse voltage.

NHN/NMN ensures the safe operation of motors under complex working conditions.

High Temperature Stability: NHN/NMN materials can operate continuously at 180°C.

Heat Aging Resistance: Maintains mechanical and electrical properties in high-temperature environments.

Thermal Shock Resistance: Adapts to rapid temperature changes during motor start-up and shutdown.

NHN/NMN is suitable for high-temperature, high-load, and continuous operation, effectively extending motor lifespan.

Tear Resistance: The Nomex® layer provides good mechanical toughness.

Flexibility: Facilitates processing and installation, adapting to complex shapes.

Puncture Resistance: Prevents mechanical damage during winding.

NHN/NMN has good compatibility with paints, resins, transformer oils, and common cooling media. It is suitable for impregnation and VPI vacuum pressure impregnation processes.

Temperature Rating Matching: Select the appropriate heat resistance rating based on the motor’s operating temperature.

Thickness Selection: Choose a suitable material thickness based on voltage level and space constraints.

Compatibility Testing: Confirm compatibility between the insulation material and impregnating varnish, encapsulation materials, etc.

Processing Technology: Optimize punching, forming, and installation processes to fully utilize material performance.

Cost-Benefit Analysis: Comprehensively calculate initial costs and lifecycle costs.

The motor industry is moving towards higher efficiency and higher reliability. NHN/NMN composite insulation materials, with their excellent heat resistance, electrical properties, and processing adaptability, have become a key material for motor insulation systems. Appropriate selection of NHN or NMN can not only improve the overall performance of the motor but also reduce operating failure rates and total lifecycle costs.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……