In modern motor manufacturing, the selection of insulation materials directly determines the reliability, service life, and operational performance of equipment. NHN and NMN are two types of high-performance composite insulation materials and are core components of motor insulation systems. This article will analyze in detail the composition, structure, and physical properties of these two materials, explaining their key roles in motor applications, providing comprehensive technical reference for motor manufacturers, technical engineers, and equipment maintenance personnel.

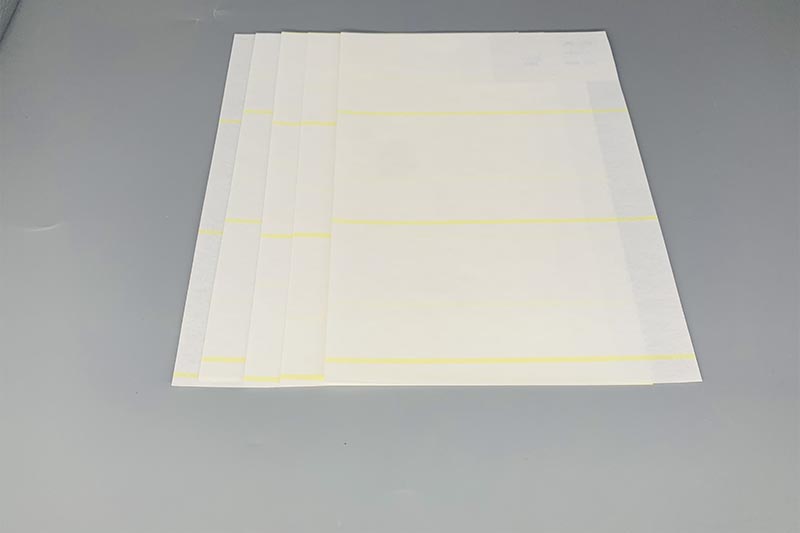

NHN has a three-layer composite structure:

Outer layer: Two layers of DuPont Nomex

Middle layer: Polyimide film

Bonding method: Composite molding using high-performance adhesives through hot pressing process

Nomex paper has good heat resistance and mechanical strength, while polyimide film has good dielectric strength and chemical resistance. The combination of these two materials achieves complementary performance.

NMN also uses a three-layer composite design:

Top layer: Nomex

Middle layer: Polyester film

Bottom layer: Nomex

Adhesion process: Hot-pressing composite technology

The addition of polyester film enhances the material’s flexibility while controlling material costs and ensuring good insulation performance.

NHN and NMN composite insulation paper can operate stably for extended periods in high-temperature environments, meeting the thermal load requirements of motors operating at high efficiency.

Both composite materials exhibit excellent electrical insulation properties, effectively preventing current leakage and short-circuit faults, thus improving motor safety and operating efficiency.

The organic components of the NMN composite material enhance its mechanical strength, enabling the motor insulation layer to withstand greater mechanical stress and preventing cracking or damage under high load conditions.

The inorganic components of NHN materials improve corrosion resistance, making it suitable for special applications such as humid environments and those with strong chemical corrosion.

NHN and NMN composite insulation materials effectively suppress arc generation, reducing the probability of motor failure, extending motor lifespan, and reducing equipment maintenance costs.

The core function of insulation materials is to isolate current and prevent short circuits between electrical components. The excellent electrical insulation properties of NHN and NMN composite materials ensure stable current flow within the motor, improving motor efficiency and operational reliability.

Motors generate significant heat during operation. Excessive temperatures accelerate the aging of insulation materials, shortening motor lifespan. The high-temperature resistance of NHN and NMN materials withstands the heat generated during motor operation, ensuring long-term stable operation.

The excellent mechanical properties and corrosion resistance of NHN and NMN composite insulation paper reduce motor failures caused by material fatigue or chemical corrosion, improving equipment reliability and reducing maintenance frequency and downtime.

High-quality insulation materials slow down the aging process of motors, reducing performance degradation caused by insulation damage. The excellent durability and stability of NHN and NMN materials significantly extend motor lifespan and reduce overall equipment operating costs.

In motor manufacturing and applications, the main application scenarios of NHN and NMN include the following:

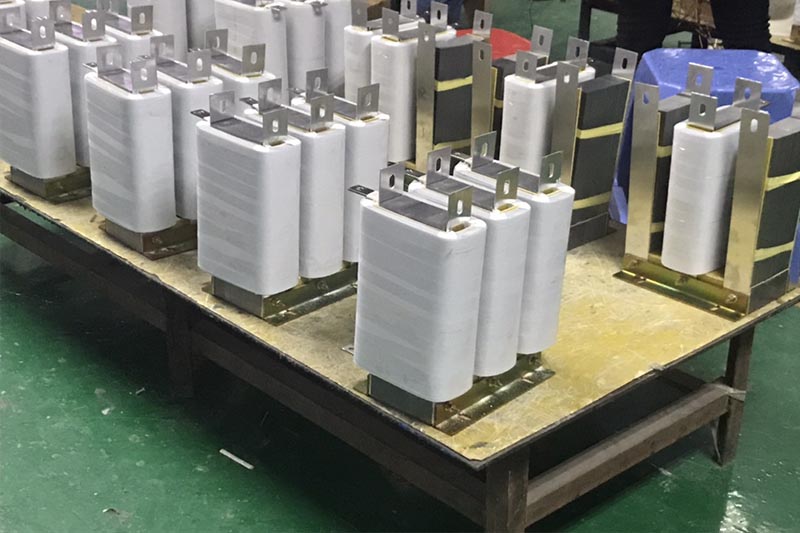

NHN and NMN composite materials can be used as insulation layers for motor windings, effectively preventing current leakage, improving motor operating efficiency, and reducing equipment failure rates.

Both types of composite materials have excellent electrical insulation and high-temperature resistance, making them suitable for insulation protection of motor stators and rotors, ensuring motor operational stability and long-term working capacity.

In high-voltage motors, NHN and NMN composite insulation paper provides higher withstand voltage, ensuring safe operation of the motor under high-voltage conditions.

NHN and NMN composite insulation materials represent a mature solution for modern motor insulation technology. Through reasonable material combinations, both types of insulation materials can simultaneously meet the requirements for electrical strength, thermal stability, mechanical protection capabilities, and environmental tolerance. The proper selection and application of these two materials can significantly improve motor reliability and service life, supporting the development of motor products towards higher efficiency, smaller size, and wider application environments.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……