In modern motor manufacturing, the reliability of the winding insulation system directly determines the motor’s operational safety, service life, and energy efficiency. NHN flexible insulation material for motor windings is a technologically mature and widely used composite insulation material. With its excellent heat resistance, mechanical strength, and electrical properties, it has become one of the key materials for mid-to-high-end motor winding insulation systems.

This article provides a systematic analysis of NHN from four aspects: material structure, performance characteristics, motor winding application methods, and selection advantages, helping motor manufacturers and engineers understand and apply this insulation material.

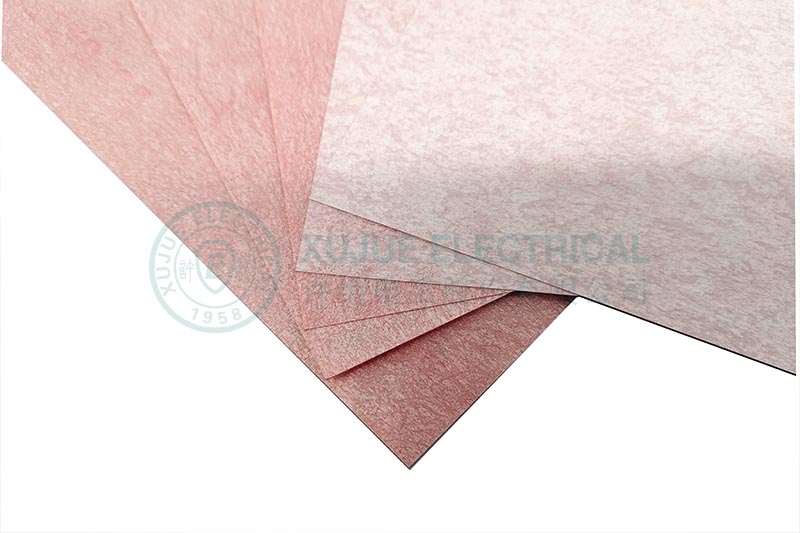

NHN is a flexible composite insulation material. It is made by laminating one or more layers of polyimide (PI) film with Nomex® aramid paper using a high-performance adhesive. This composite structure integrates the superior properties of two substrates:

♦ Polyimide film layer: Provides high dielectric strength, high temperature resistance, and mechanical toughness

♦ Nomex® aramid paper layer: Provides good flexibility, tear resistance, and impregnation properties

♦ Advantages of the composite structure: Compared to single insulating materials, NHN exhibits significantly improved dimensional stability, corona resistance, and mechanical strength at high temperatures.

NHN flexible insulation material can operate stably at 180℃ for extended periods. It is suitable for high-temperature, high-load motor environments, extending motor lifespan.

NHN possesses high dielectric strength, stable breakdown voltage, and good corona resistance. It ensures the safety of motor windings under high-voltage, high-frequency operating conditions.

NHN material is soft, flexurally resistant, and tear-resistant, making it suitable for:

High-slot full-rate windings

Automatic winding and high-speed winding processes

Motor designs with complex winding structures

NHN exhibits good resistance to transformer oil, insulating varnish, resins, and common solvents. It maintains stable performance during long-term transformer operation.

NHN is widely used in motor stator slot insulation to achieve electrical isolation between the winding and the core. It is particularly effective in high-voltage and high-power-density motors.

NHN, as a flexible insulation material, is used for phase-to-phase and interlayer insulation in motor windings to prevent short circuits between windings and improve the overall insulation level of the motor.

Due to its good flexibility, NHN can be used to wrap the winding ends, improving the reliability of local insulation in the motor.

Selecting suitable NHN materials requires comprehensive consideration of the motor voltage level, operating environment, temperature rise design specifications, and manufacturing process requirements.

Generally, the higher the motor voltage and the harsher the operating conditions, the higher the required thickness and performance level of the insulation material. In practical applications, it is recommended to collaborate with material suppliers to conduct targeted compatibility testing and optimize process parameters, including wrapping tension, overlap ratio, impregnation process, and curing procedure, to fully utilize the material’s performance.

During material installation and handling, contact between the material and sharp parts must be avoided. Standardized wrapping procedures must be followed to ensure a uniform and dense insulation layer. Pre-baking before impregnation, proper vacuum control, and curing cycle settings are crucial steps in ensuring the quality of the final insulation system.

NHN flexible insulation material for motor windings represents the current advanced level of motor insulation technology. Applying this material can improve motor performance, reliability, and service life. By understanding the material’s properties and implementing standardized applications, motor designers and manufacturers can meet technical challenges and develop high-performance motor products.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……