GPO-3 (UPGM203) composite sheets comply with RoHS/REACH standards and have passed UL and EN45545 dual certifications.

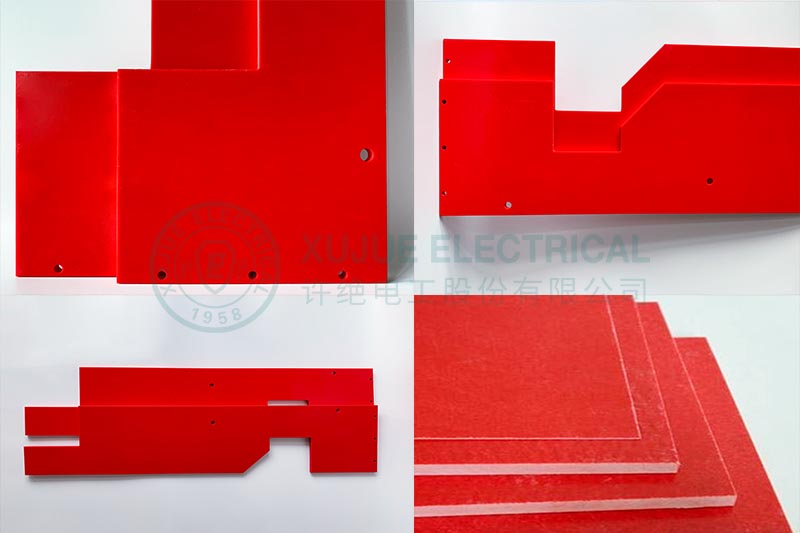

GPO-3 composite sheets use glass fiber and polyester resin as the core material. And it is made by impregnating alkali-free glass mat with unsaturated polyester resin and then laminating under high temperature and pressure. It can be processed into various UPGM composite sheets and matching parts.

GPO-3 possesses excellent electrical properties (electrochemical insulation, arc insulation, etc.) and mechanical properties.

Its thickness ranges from 0.5-60mm.

Sheet size is 2100mm × 1230mm.

Thickness tolerance is better than GB and IEC standards.

Thickness can be customized, supporting 1/2 inch, 3/8 inch, and other specifications.

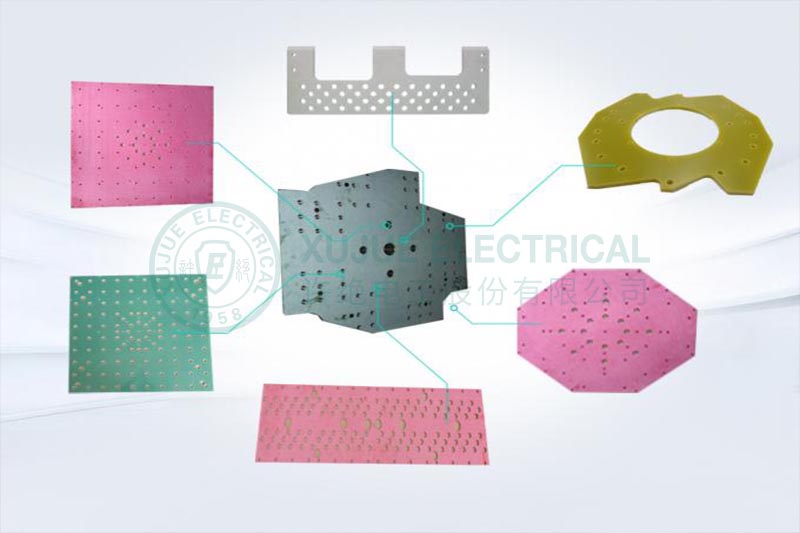

Special colors such as yellow can be customized with sufficient orders.

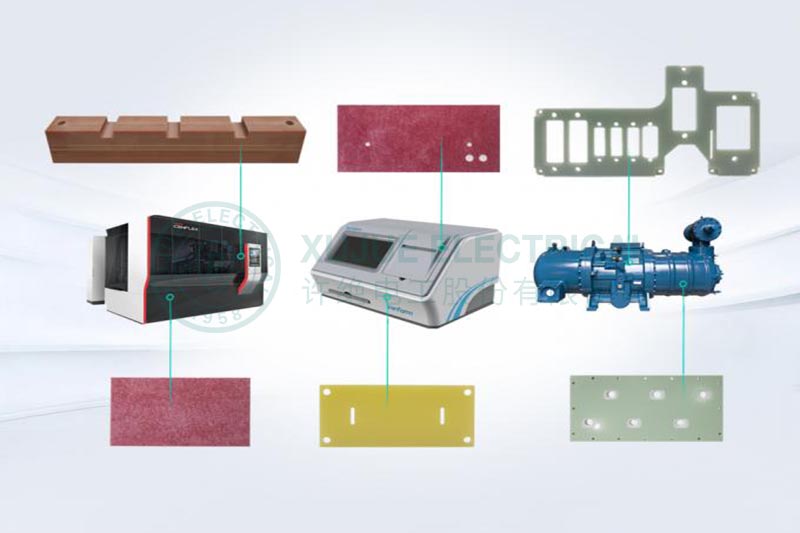

It is compatible with CNC machining, making processing convenient and efficient.

Its performance is outstanding, with an arc resistance test exceeding 180 seconds.

It is environmentally friendly and have passed RoHS/REACH.

Customization based on provided drawings is supported to meet individual needs.

GPO-3 is widely used in the manufacture of insulating structural components for electrical equipment such as F-class motors, transformers, switchgear, circuit breakers, frequency converters, and high-voltage distribution cabinets. UPGM material can be directly molded into various custom profiles.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……