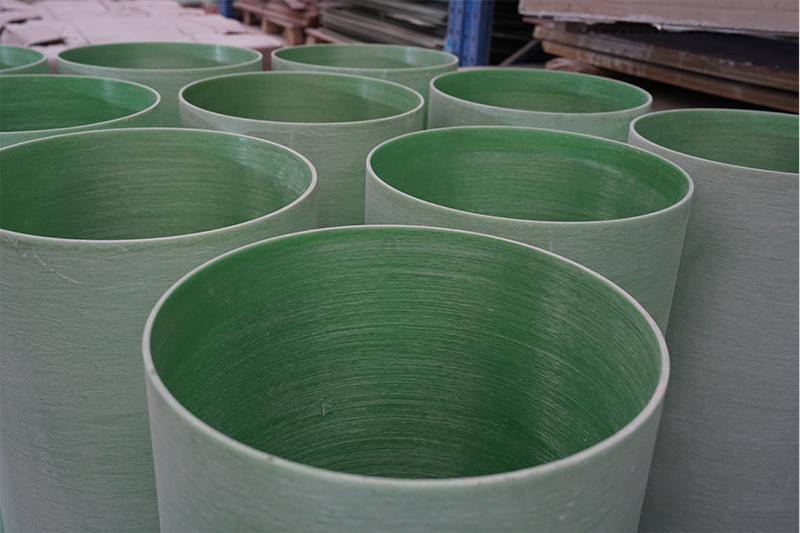

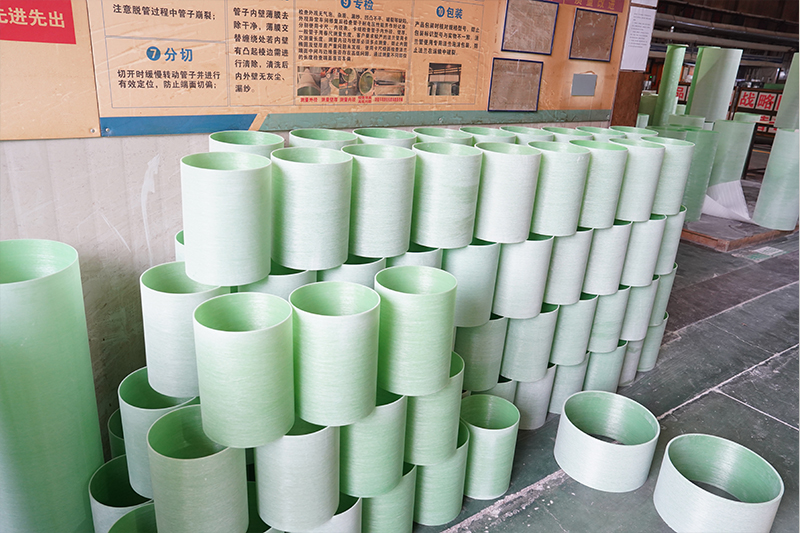

G10 is a grade specified by the National Electrical Manufacturers Association (NEMA) standard. It is a laminate or tube made from continuous alkali-free glass fiber yarn as reinforcement, impregnated with epoxy resin, and then cured under high temperature and pressure. Winding is the primary manufacturing method for tube, offering the best performance.

The roles of two key materials are as follows:

Glass fiber yarn: Provides high tensile strength and stiffness.

Epoxy resin: Serves as a base material, bonding the fibers together, transmitting and distributing forces, and providing corrosion resistance and electrical insulation.

Resin-impregnated continuous glass fiber yarn is continuously wound onto a rotating mandrel according to a pre-determined winding pattern (linear pattern) under precisely controlled tension. After curing and demolding, the resulting hollow composite tube is obtained.

Depending on the process, winding techniques are primarily categorized into three types, each with its own application scenarios:

1. Wet Winding

After being pulled from the creel, the fiber yarn is directly passed through a resin tank for impregnation and then immediately wound onto a mandrel.

Advantages: The resin dosage can be adjusted in real time, the equipment is simple, the cost is low, and it can accommodate a wide range of pipe specifications.

Disadvantages: High levels of resin volatiles, a poor working environment, and slightly greater difficulty controlling product quality.

Application: Currently, this is the most commonly used winding method for producing G10 pipe.

2. Dry Winding

The fiber is first impregnated with resin to form a prepreg (a dry, semi-finished product). During winding, the prepreg is heated to soften it and then wound onto a mandrel.

Advantages: Precise control of resin dosage, stable product quality, and a clean working environment.

Disadvantages: Prepreg is expensive, requires refrigerated storage, and requires significant equipment investment.

Applications: Mostly used in high-end applications such as aerospace, which require high product quality.

3. Semi-Dry Winding

After impregnation, the fiber is passed through a drying oven to remove some solvents and volatiles before winding.

Advantages: Combines the advantages of wet and dry winding, reducing air bubbles and volatiles in the product.

Disadvantages: The additional drying step requires additional equipment.

Based on a combination of cost and flexibility, wet winding remains the primary choice for producing G10 tube.

The production of G10 tube involves four key steps: material selection, molding, baking, and post-processing. Each step significantly impacts the quality of the final product:

Choosing the right material is crucial for ensuring product quality. Currently, aluminum-silicon composite glass fiber is the most effective material for glass fiber filament winding tube in the industry. This material offers excellent strength, hardness, density, and stability, and can operate normally even in high-temperature environments.

Molding is the core process of pipe manufacturing and consists of three main steps:

√ Mold Design: Design and manufacture a suitable mold based on the size and shape of the desired glass-wound pipe.

√ Glass-Wounding:

Impregnation: The fiber yarn passes through a tension control system and enters the resin tank, where it is thoroughly saturated with epoxy resin.

Winding Nozzle Movement and Mandrel Rotation: This is the core technology. The winding machine controls the “winding nozzle” (the device that guides the fiber) to move back and forth along the mandrel axis while the mandrel rotates at high speed. By precisely controlling the speed ratio of the two, a specific winding pattern (line shape) is achieved.

√ Winding Line Shapes:

Circumferential Winding: The fibers are wound almost perpendicular to the pipe axis, primarily improving the pipe’s circumferential strength and resistance to internal pressure.

Spiral Winding: The fibers are wound at a specific angle (such as ±45° or ±30°) to the pipe axis, primarily improving the pipe’s axial strength, torsional stiffness, and bending resistance.

G10 pipes typically use a combination of “spiral winding and circumferential winding.” By adjusting the ratio and angle of the two winding methods, the mechanical properties of the pipe in different directions can be adjusted to meet specific requirements.

√ Baking: The formed glass fiber wrapped tube is placed in a baking oven for heating. The oven temperature and duration should be adjusted according to actual conditions; generally, the temperature should be slightly higher than the cycloidal temperature during forming.

Post-processing consists of three main steps to ensure product precision and appearance:

Unloading: After the glass fiber wrapped tube has completely cooled in the oven, it is removed from the mold.

Deburring: Remove burrs and imperfections from the surface of the wrapped tube, ensuring a smooth, even finish that is less susceptible to scratches and damage.

Inspection: Inspect the appearance, dimensions, and performance of the wrapped tube to ensure that the finished product meets quality requirements.

During winding, it is crucial to apply stable and uniform tension to each fiber. Too little tension results in a loose product structure and low strength; too much tension can cause fiber wear and stress on the inner fibers, potentially damaging the structure. A precise tension control system is key to producing high-quality winding tubing.

The resin content (typically controlled between 20% and 35%) directly affects the product’s mechanical properties and heat resistance. The fibers must be completely saturated with resin, eliminating any “white strands” (unsaturated dry fibers) or air bubbles.

Even the slightest deviation in the winding angle can significantly alter the tube’s performance. Advanced CNC winding machines now use software to precisely control the movement of the winding nozzle and mandrel, ensuring repeatable winding patterns.

Curing is the process by which the resin undergoes a chemical reaction. The heating rate, curing temperature, and holding time must be strictly controlled according to the resin’s characteristics. Improper curing can result in insufficient product strength, excessive internal stress, and even cracking.

Choosing the right release agent and applying it evenly are crucial. Failure to release the mold can damage both the product and the expensive core mold.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……