The black FR4 antistatic fiberglass board is made of glass fiber and antistatic resin. The antistatic function is integrated into the FR4 substrate through a special process. It has both mechanical strength, insulation performance and electrostatic protection capabilities. Its core advantages are reflected in five aspects.

The surface resistance value of the black FR4 antistatic board is stable and meets the ESD protection standard. It can eliminate static electricity accumulation and avoid damage to electronic components due to static electricity breakdown. It can reduce the product defect rate in scenarios such as semiconductor manufacturing and electronic packaging.

The black FR4 antistatic board adopts an overall antistatic process (non-surface coating). After mechanical processing or long-term use, the surface wear remains stable. It is suitable for electronic test fixtures, PCB test racks and other scenarios, solving the problem of easy failure of traditional coating materials.

The glass fiber and epoxy resin composite structure of the black FR4 anti-static board makes it have high bending strength, can withstand mechanical processing stress, and is not easy to deform and crack. It can ensure stable operation under vibration and impact environment in motor equipment and automated machinery.

The surface of the black FR4 anti-static board is smooth and flat, suitable for precision component manufacturing. It is not easy to produce burrs or plugging holes during mechanical processing, supports mass production, and can reduce light scattering and assembly errors in optical instruments and precision testing equipment.

Black FR4 antistatic fiberglass board can be used for a long time in high temperature environment, and has excellent short-term high temperature resistance. It is suitable for scenes such as transformer interior and motor winding, and can prevent itself from deformation or insulation failure due to high temperature.

Black FR4 antistatic fiberglass board has low water absorption rate and stable wet electrical performance. It has also high flame retardant grade, which can extinguishes immediately when away from fire and meets safety regulations. It is suitable for humid environments, outdoor electrical boxes and fire risk scenes.

Black FR4 antistatic board is resistant to oil, weak acid and weak alkali, and can be used for a long time in environments such as transformer oil and chemical media, and can reduce maintenance costs in chemical equipment and outdoor electrical facilities.

Black FR4 antistatic fiberglass board has low dielectric constant and low dielectric loss, which is suitable for high-frequency circuit applications. It can reduce signal attenuation and improve transmission efficiency in communication equipment and radio frequency devices.

The black FR4 anti-static board has a high volume resistivity and can be used as an insulating structural component for high-voltage switches, motors and electrical appliances to prevent arc breakdown and ensure the safe operation of the power system.

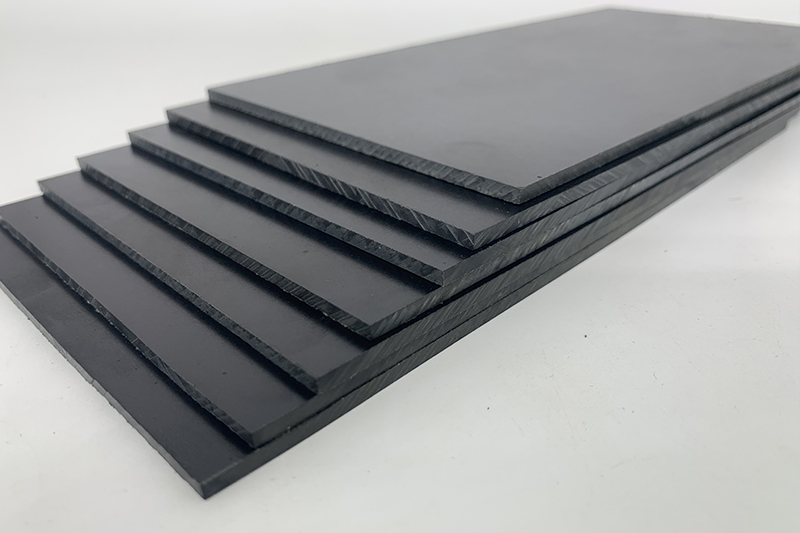

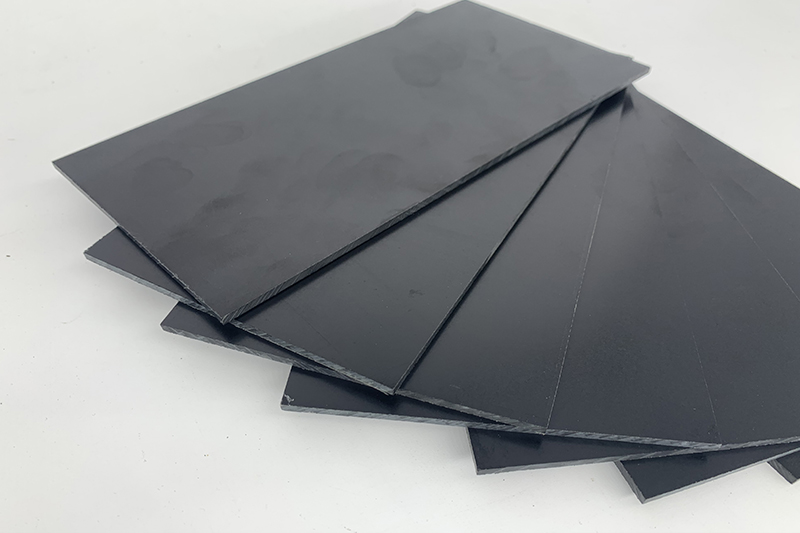

The black FR4 anti-static fiberglass boards are available in solid black, surface black (with aqua green core), and double-sided designs (one side anti-static, the other insulated), catering to various scenarios such as cleanroom decoration and localized static control.

Black FR4 anti-static fiberglass boards come in multiple standard specifications, with customizable thickness and dimensions. Thickened panels can enhance strength for large equipment, while thin panels save space for precision instruments.

Black FR4 anti-static boards include fully anti-static, layered anti-static, and single-sided anti-static types. It is suitable for applications such as semiconductor manufacturing equipment, composite structural components, and electronic packaging trays.

Black FR4 anti-static fiberglass boards integrate anti-static properties, mechanical strength, environmental adaptability, and electrical performance, making them an ideal material for electronics, electrical engineering, precision manufacturing, and other fields. Their comprehensive performance meets the demands of various scenarios, providing reliable solutions for industries such as semiconductor manufacturing, motor equipment, and communication devices, thereby enhancing efficiency and reliability.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……