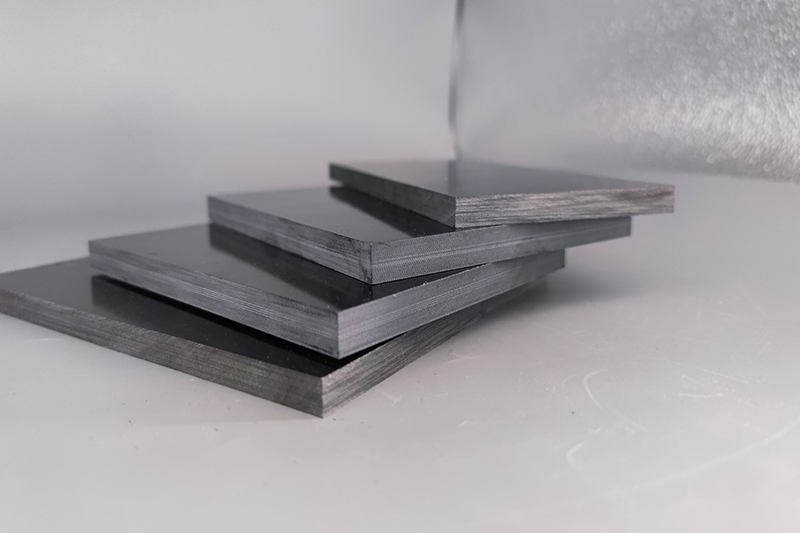

In high-precision fields such as electronic manufacturing, aerospace, and medical equipment, engineers’ decisions when choosing materials for printed circuit boards (PCBs) are directly related to product performance and reliability. FR4 is currently the most widely used PCB substrate, and its antistatic improved version – especially black FR4 antistatic board, has continued to increase in popularity in the field of high-end manufacturing in recent years. This article will systematically analyze the core reasons for the industry’s selection of black FR4 anti-static board and its technical advantages.

FR4 is a composite substrate material with glass fiber cloth as the reinforcement skeleton and epoxy resin as the matrix. Its core performance advantages are reflected in:

Excellent mechanical properties: The synergistic effect of glass fiber and resin gives the material high strength and excellent dimensional stability, enabling it to withstand mechanical stress during processing and use.

Reliable electrical insulation: The material has high volume resistivity and surface resistivity, meeting the basic requirements of insulation protection.

Excellent heat resistance: Its glass transition temperature (Tg value) is usually in the range of 130-180℃, which can adapt to the working temperature rise environment of electronic equipment.

Outstanding chemical stability: FR4 has good tolerance to most industrial solvents, acids and alkalis, which can extend its service life.

In the electronic manufacturing environment, the hazards caused by electrostatic discharge (ESD) run through the entire life cycle of the product:

· It will directly lead to potential damage to electrostatic sensitive semiconductor devices (such as MOS tubes and sensors).

· This phenomenon causes yield fluctuations in the production process and increases manufacturing costs.

· Electrostatic discharge causes sudden failures in equipment operation and even threatens system safety.

· It will also bury long-term reliability risks and shorten the service life of the product.

Professional anti-static treatment achieves protection through a triple mechanism:

· The treatment process stabilizes the surface resistance in a safe range of 10⁶-10⁹Ω.

· Anti-static materials build a controllable static charge discharge path to avoid charge accumulation.

· Related technologies form a continuous and effective anti-static barrier to reduce environmental electrostatic interference.

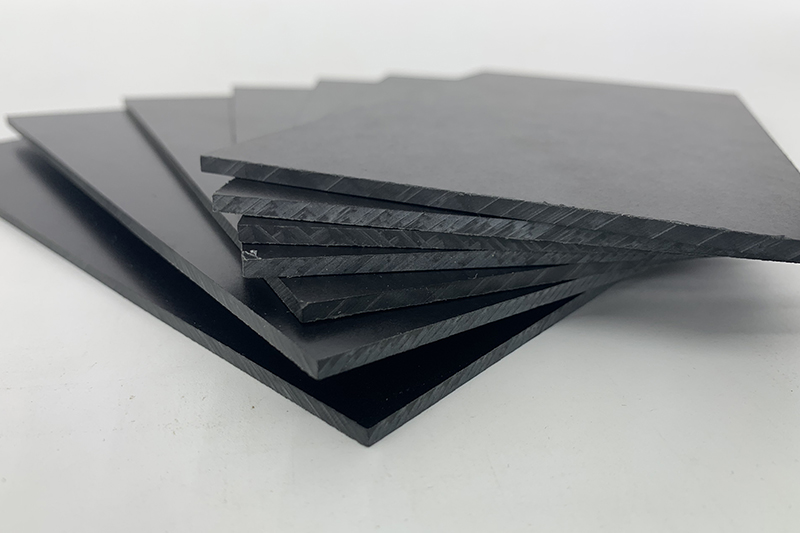

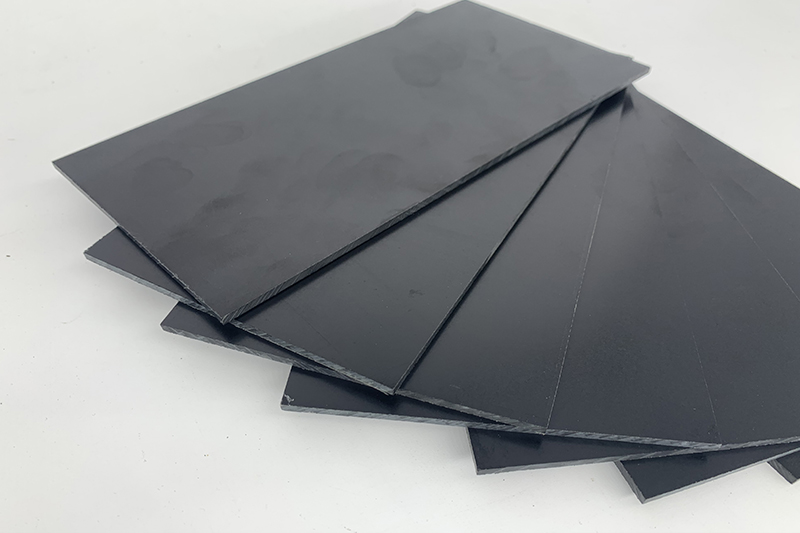

Optical optimization: The black surface significantly reduces the surface light reflectivity. In scenes with high light sensitivity such as optical detection equipment and camera modules, it can reduce stray light interference and improve detection accuracy

Design adaptation: The board meets the requirements of high-end electronic products for appearance texture, especially for minimalist design style

Logo clarity: White silk screen printing forms a strong contrast on the black substrate, making circuit logos and component numbers easier to identify, and convenient for later maintenance and repair

Black FR4 anti-static board achieves performance breakthroughs through innovative processes:

Manufacturers use integrated molding technology in which carbon powder or conductive fillers are evenly dispersed in the resin matrix to avoid the performance attenuation problem of traditional coating processes.

Its surface resistance is less affected by environmental factors such as temperature and humidity, and can remain stable under complex working conditions.

The anti-static component forms a molecular-level bond with the substrate, significantly improving wear resistance and extending the service life by more than 30%.

Thermal management optimization: The thermal emissivity of the black surface is 20%-30% higher than that of the light-colored plate, which can accelerate the heat dissipation of the equipment and reduce the risk of local overheating.

Environmental tolerance: The plate has better anti-ultraviolet aging performance than the light-colored version, and is more durable in outdoor or long-term light environments.

Production consistency: Its color uniformity is strictly controlled, and the color difference and performance. fluctuation between different batches are extremely small, ensuring the stability of large-scale production.

Due to its comprehensive advantages, black FR4 anti-static board is irreplaceable in the following fields:

High-precision electronic equipment field: Such as medical imaging instruments, precision test and measurement. equipment, these equipment must meet the requirements of anti-static and optical stability at the same time.

Optical system component field: Such as Camera modules, laser sensors, etc., these equipment rely on low reflective properties to ensure optical performance.

Industrial automation environment: In production workshops with high electrostatic risks, this plate can reduce the equipment failure rate.

High-end consumer electronics field: Such as flagship smartphones, professional-grade wearable devices, these products take into account both performance and appearance design requirements.

Black FR4 anti-static fiberglass board is not a simple “Color improvement” and it is the deep adaptation of material properties, protective functions and application scenarios. Its popularity in the field of high-end manufacturing reflects the electronics industry’s refined pursuit of comprehensive material performance.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……