What is G11 fiberglass sheet made of? What role does it play in practical applications? Perhaps many people will confuse it with ordinary glass, but in fact, G11 fiberglass sheet is a high-performance material made of glass fiber and resin. It is worth noting that although glass fiber and carbon fiber are both widely used materials at present, there are significant differences between the two in essence:

Different chemical composition: Glass fiber is an inorganic non-metallic material with excellent performance. Its outstanding advantages include excellent insulation ability, strong heat resistance, excellent corrosion resistance and high mechanical strength, but it also has the disadvantages of brittle material and poor wear resistance.

Wide application field: Glass fiber is often used as a reinforcing material in composite materials and is used in national economic fields such as electrical insulation materials, thermal insulation materials, circuit substrates, etc. According to the morphology and characteristics, glass fiber can be divided into continuous fiber, fixed length fiber, and alkali-free and high alkali types.

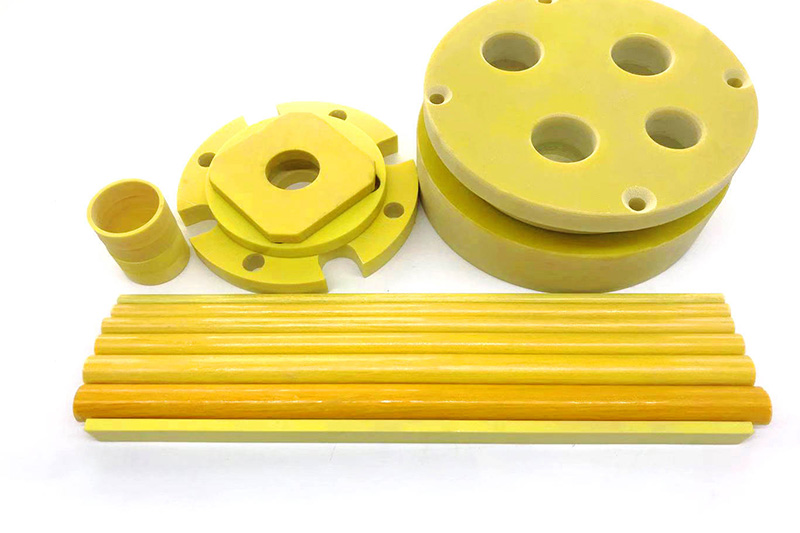

Slot wedges and insulating gaskets: G11 fiberglass sheets can be used as slot wedges and insulating gaskets for motor stators and rotors. Their core function is to prevent short circuits between coils and cores. Since the material has high temperature resistance with a long-term working temperature of 180°C and strong arc resistance, it is particularly suitable for use in high-voltage motors.

End support structure: At the end of the motor winding, G11 fiberglass sheets can provide reliable mechanical support and effectively prevent wire wear caused by vibration.

For the commutator of a DC motor, G11 fiberglass sheets can be used as insulating substrates. Their resistance to electric spark erosion can significantly extend the service life of the components.

In high temperature and high vibration environments such as electric vehicle drive motors and industrial variable frequency motors, the comprehensive performance of G11 fiberglass sheets is significantly better than that of ordinary FR-4 materials, and can stably play the role of insulation and structural support.

Switchgears and circuit breakers: G11 fiberglass board can be processed into partitions, baffles or supports to isolate high-voltage conductors, prevent creepage and breakdown, and ensure safe operation of equipment.

Transformer insulation structure: In transformers, G11 fiberglass board can be used for insulation or structural support between windings. Its excellent oil resistance and moisture resistance can adapt to the complex working environment of transformers.

Cable terminals and connectors: G11 fiberglass sheet is processed into insulating sleeves or brackets and applied to cable terminal boxes and connectors to ensure the reliability of high-voltage cable connections.

In new energy equipment such as photovoltaic inverters and wind power converters, G11 fiberglass board can be used as circuit board substrates and insulating structural parts. Its strong weather resistance can adapt to complex outdoor climate conditions.

Motor field case: Using G11 slot wedges in electric vehicle drive motors can greatly reduce the risk of deformation in high temperature environments and ensure the stability of motor operation.

Power grid field case: G11 insulating partitions are used in high-voltage switchgear, which can maintain excellent insulation performance for more than 10 years even in humid environments.

When the ambient temperature is close to or exceeds the temperature resistance limit of the material (such as F-class motors, high-temperature fans, etc.);

In high humidity environments or when the equipment needs to be exposed to oil and chemical media for a long time (such as offshore wind power, chemical equipment, etc.);

For high voltage levels or scenarios with strict insulation reliability requirements (such as high-voltage switchgear, transformers, etc.);

When the equipment has extremely high requirements for weight, precision or extreme environmental adaptability (such as aerospace, medical equipment, etc.).

Regular scenarios with moderate and dry ambient temperatures (such as conventional low-voltage motors, indoor distribution boxes, etc.);

Scenarios with relatively sensitive budgets and acceptable equipment maintenance cycles (such as civil building electrical, general industrial equipment, etc.).

Through the analysis of the application of G11 sheet in the field of motors and power grids, it can be seen that it has become an indispensable basic material in high-end electrical equipment with its excellent comprehensive performance, and a reasonable selection strategy can further optimize the reliability and economy of the equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……