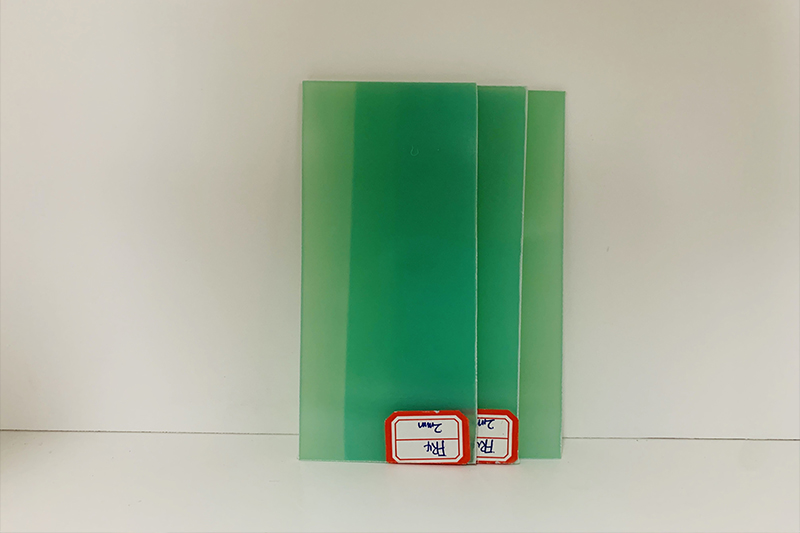

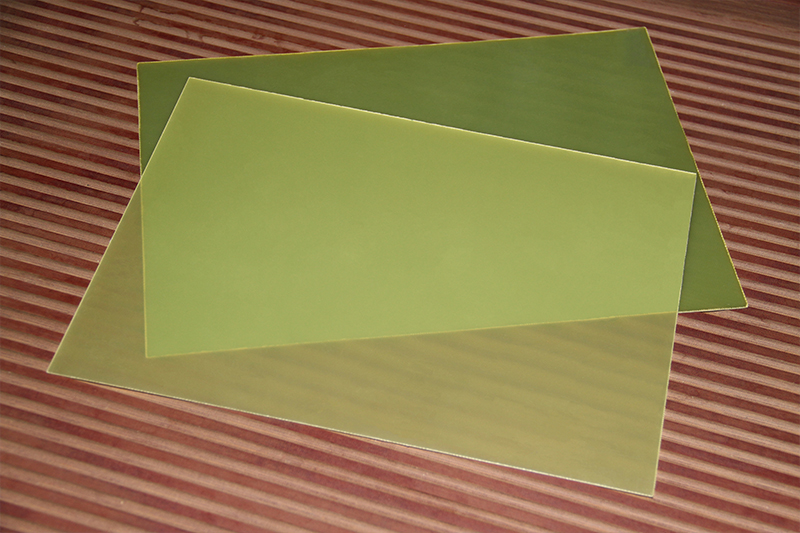

In generator manufacturing and maintenance, the selection of insulation materials directly determines electrical safety, mechanical stability, and long-term operational reliability. G10 and FR4 are both commonly used epoxy glass cloth laminated sheets. Their properties are similar and widely applicable. And they are frequently compared when selecting materials for similar applications. This article provides a comprehensive analysis of their specific differences in generator applications and offers selection recommendations for different working conditions.

Although both G10 and FR4 are made from fiberglass cloth and epoxy resin through lamination, their main differences lie in flame resistance and environmental adaptability:

FR4 contains flame-retardant additives in its resin system and meets the UL94 V-0 flame-retardant standard. It is suitable for generator components such as winding supports and other electrical parts requiring high fire safety.

G10 has higher mechanical strength but does not have flame-retardant properties. It is used in applications with no open-flame risk and where higher mechanical load capacity is required.

G10 has a lower moisture absorption rate, making it suitable for humid or hot environments, or generator parts that may be exposed to moisture for long periods.

FR4, because it contains flame-retardant additives, has slightly higher moisture absorption than G10. However, its value remains well within the safe range for generator applications.

Both G10 and FR4 offer electrical insulation, flexural strength, and mechanical stability that meet the requirements of key generator components such as end brackets, support blocks, and insulation barriers.

Their overall performance can be summarized as:

G10: Slightly higher mechanical strength.

FR4: More stable electrical performance and broader application adaptability.

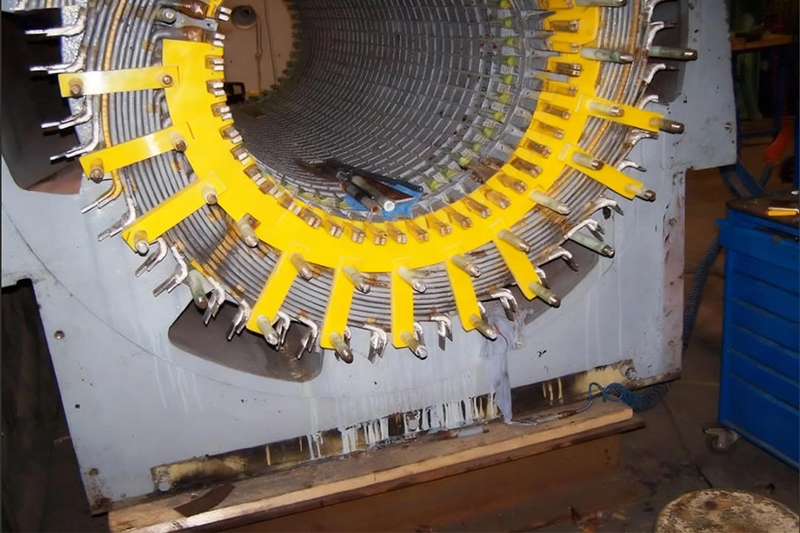

Stator winding slot wedges

Insulation barriers and end supports

Busbar supports and fixing components

Rotor coil insulation structural parts

Electrical insulation panels inside generator control cabinets

Structural supports subjected to high mechanical loads

Insulation components used in high-humidity environments

Custom-machined irregular insulation parts

Components that do not require flame retardancy but demand high mechanical strength

When mechanical strength is the primary selection criterion: Such as structural supports in large generators.

When equipment must operate in extreme environments: Such as marine generators exposed to salt-spray conditions.

For ultra-high-voltage conditions: Maximum dielectric strength is required.

When precision machining is necessary: G10 provides better dimensional stability during processing.

When safety regulations mandate the use of flame-retardant materials: Such as generators in commercial buildings, public transportation, or data centers.

For cost-sensitive projects: Such as standard-size insulation barriers, gaskets, and other general components.

For electronic integration parts: Such as circuit-board supports in generator control systems.

When industry certifications (UL, CE, etc.) require specific flame-retardant performance.

♦ Neglecting thermal expansion coefficient: In environments with significant temperature fluctuations, the thermal expansion characteristics of epoxy boards are not properly matched with adjacent metal components.

♦ Overlooking long-term aging effects: In FR4, flame-retardant additives may migrate over time, affecting long-term material performance.

♦ Over-specifying materials: Selecting high-grade materials without considering the actual functional requirements of the component.

♦ Neglecting machining feasibility: Both materials needed special tools for machining, and the machining conditions were not considered in advance during the design stage.

Regular Inspection: Conduct at least one physical inspection of insulation materials every year.

Identifying Abnormal Signs: Focus on detecting cracks, discoloration, delamination, or carbonization on the material.

Cleaning Requirements: Use non-corrosive cleaning agents to prevent damage to the resin surface layer.

Replacement Criteria: Replace the material immediately if permanent deformation is observed or if electrical performance tests fail to meet standards.

G10 and FR4 are both high-quality insulation materials for generator applications. G10 offers significant advantages in mechanical strength and stability under extreme environments, while FR4 provides superior flame-retardant safety and cost-effectiveness. Actual material selection should consider application conditions, performance requirements, safety regulations, and economic factors to ensure the material matches the operational needs of the equipment.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……