In modern generator design and manufacturing, the selection of insulation materials directly determines equipment performance, operational safety, and service life. As a high-performance insulation material, FR4 epoxy sheet—thanks to its stable electrical, mechanical, and thermal properties—has become an essential component in key generator structures. This article explains the core applications of FR4 epoxy sheet in generators and its importance in ensuring stable operation of power equipment.

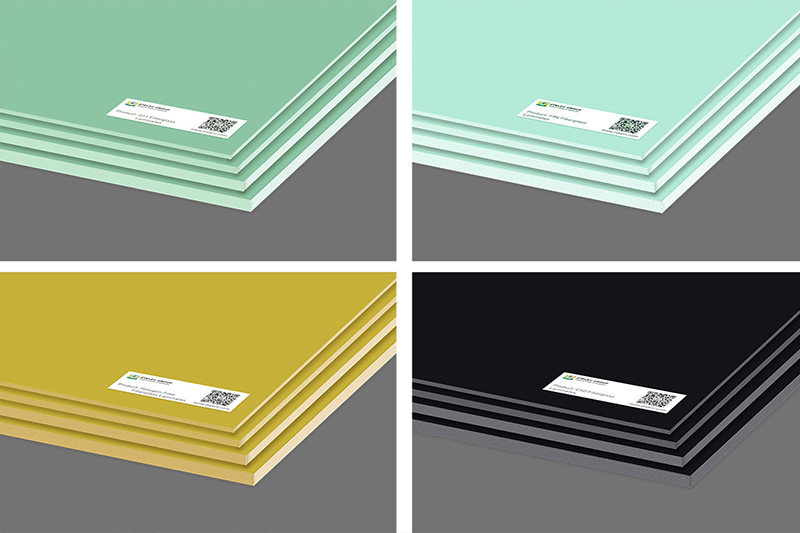

FR4 epoxy sheet is an insulating laminate made from fiberglass cloth and epoxy resin through high-temperature and high-pressure pressing. The “FR” in its name stands for “Flame Retardant.” The material offers excellent electrical insulation, mechanical strength, heat resistance, and chemical corrosion resistance. It can maintain stable performance even in humid environments, fully meeting the stringent operating conditions required in generators.

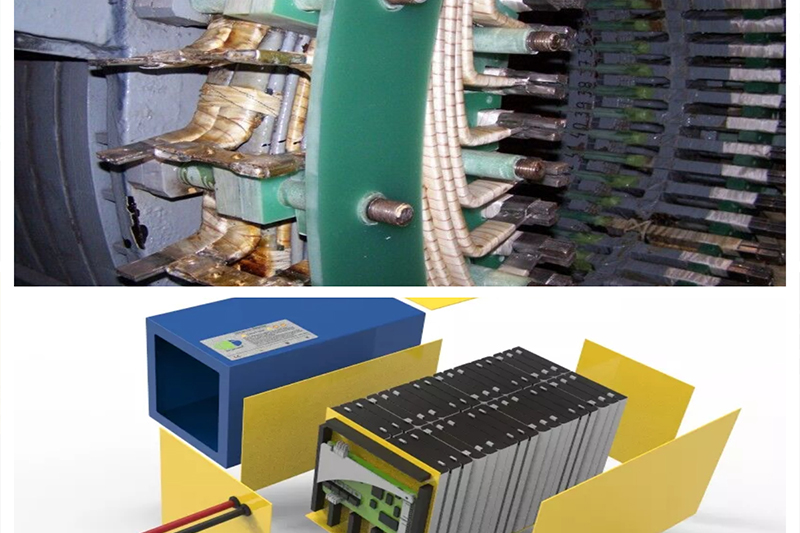

Due to its high mechanical strength and excellent electrical properties, FR4 epoxy sheet is widely used for generator stator slot wedges and slot insulation. Its main functions include:

Protecting stator coils from mechanical damage

Securing coil positioning to prevent vibration or displacement during operation

Enhancing the insulation level in slot areas to avoid partial discharge and insulation breakdown

During high-speed generator operation, end windings are subjected to centrifugal forces and tend to shift, requiring strong support structures for stabilization. Common FR4 machined parts used for end-winding support include:

End-winding support rings

Insulation barriers

Fixing blocks

With high mechanical strength and dimensional stability, FR4 components ensure that the end windings remain securely fixed throughout long-term generator operation.

To prevent flashover or short-circuit faults between the three-phase windings, FR4 epoxy sheet is widely used to manufacture interphase insulation components, including:

Interphase barriers

Bridge-type insulation pieces

Isolation covers

The arc-resistant properties and high dielectric strength of FR4 effectively enhance the overall safety of interphase insulation in generators.

FR4 epoxy sheet has excellent machinability and is compatible with CNC processing, allowing it to be fabricated into various non-standard insulation components, such as:

Insulation gaskets and spacers

Small insulation brackets and positioning plates

End-cover insulation baffles

Although these components are small in size, they play a critical role in ensuring the stability of the generator’s overall insulation system.

Beyond the generator itself, FR4 epoxy sheet is also used in auxiliary control and protection equipment, such as:

Internal insulation panels in control cabinets

Mounting plates for relay protection modules

Terminal isolation pieces

The flame-retardant and insulating properties of FR4 significantly improve the operational safety of control and protection systems.

These generators require insulation materials with strong vibration resistance and excellent moisture resistance. FR4 epoxy sheet is mainly used for end-winding support components and interphase barriers.

Their operating environment demands insulation materials with superior resistance to moisture, water vapor, and corrosion. The low water absorption of FR4 meets these requirements well.

These units often operate under high-temperature conditions and therefore require insulation materials with higher thermal ratings, such as G11 epoxy sheet—an enhanced variant of FR4.

To ensure that FR4 epoxy sheets deliver optimal performance in generators, the following guidelines should be followed:

♦ Select the appropriate grade of FR4 epoxy sheet based on the actual voltage level, operating temperature, and mechanical load conditions of the equipment.

♦ During installation, keep the insulation material surface clean to prevent contaminants from affecting insulation performance.

♦ Conduct regular inspections of FR4 components to identify cracks, carbonization, or mechanical damage.

♦ Strictly follow the manufacturer’s specified installation torque standards and operating procedures.

From large power station units to industrial backup power systems, and from wind turbine generators to hydropower generators, FR4 epoxy sheets—thanks to their well-balanced overall properties—hold an irreplaceable position in generator insulation, support, and isolation systems. They are not only the core material to ensure the electrical safety of generator, but also the important foundation to realize the compact design and efficient and stable operation of the equipment.

With continuous advancements in insulation materials and power generation technologies, FR4 epoxy sheets will continue to play a critical role in the power industry.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……