During the design, manufacturing, and maintenance of motors, the choice of insulation system directly impacts their performance, reliability, and service life. Among numerous insulation materials, DMD insulation paper, with its high mechanical strength and reliable insulation performance, has become a widely used material among motor engineers. This article will explain in detail why DMD insulation paper is an ideal choice for motor insulation solutions.

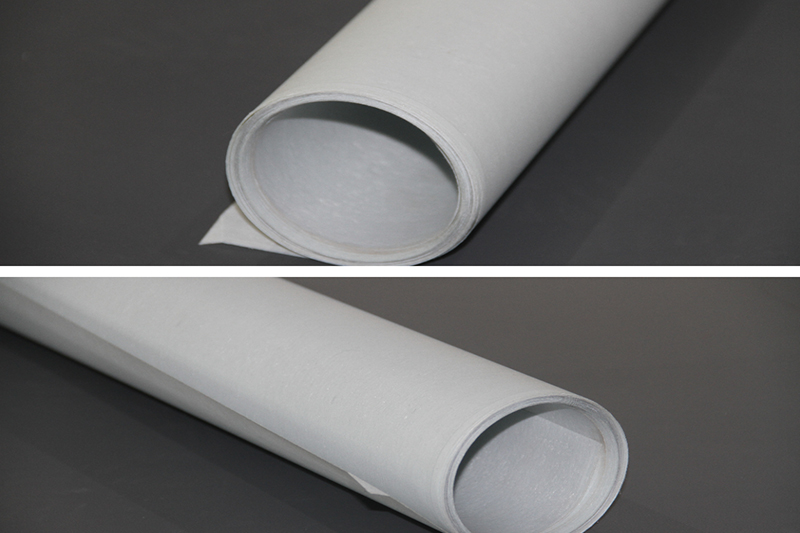

DMD insulation paper is a three-layer, H-grade composite insulation material. Its structure includes:

Outer layer: Two layers of polyester film, providing excellent electrical insulation.

Middle layer: Polyester fiber nonwoven fabric, imparting high mechanical strength and toughness.

This three-layer composite structure combines the advantages of different materials to create an insulation material with excellent overall performance.

Motors operate in complex environments, and often subject to centrifugal forces, electromagnetic vibration, thermal expansion and contraction caused by high-speed rotation, and slot stress during the manufacturing process. The polyester fiber felt layer in DMD insulation paper offers high tensile strength, tear resistance, and toughness, resulting in the following advantages:

During the winding insertion and shaping process, DMD insulation paper is less susceptible to damage, helping to ensure production quality.

Under conditions of long-term vibration and temperature fluctuations, DMD effectively resists fatigue cracking, maintaining the integrity of the insulation system and extending the life of the motor.

As an insulation material, electrical performance is crucial. The polyester film layer of DMD insulation paper has high insulation resistance and dielectric strength, offering the following advantages:

It can withstand overvoltage and surges during motor operation, preventing short circuits between turns, between phases, and to ground, ensuring safe and stable motor operation.

DMD insulation paper is typically classified as Class B, Class F , or Class H insulation material, allowing it to operate in high-temperature environments for extended periods. Its advantages include:

Excellent thermal aging resistance. Under high-temperature operating conditions, its mechanical and electrical performance degrades slowly, making it suitable for applications with high heat generation, such as high-efficiency motors and variable-frequency motors.

DMD insulation paper offers excellent resistance to moisture, grease, and various chemical solvents. Its advantages include:

It maintains stable performance in harsh industrial environments, such as those exposed to moisture and oil, preventing degradation of insulation performance due to moisture absorption or corrosion.

Due to its comprehensive performance, DMD insulation paper is widely used in the insulation systems of the following motors:

♦ Variable frequency motors: Withstand the high-frequency pulse voltages generated by inverters.

♦ High-voltage motors: Provide reliable interlayer and interphase insulation.

♦ Explosion-proof motors: Ensure safe operation in harsh environments.

♦ New energy vehicle drive motors: Meet high power density and high reliability requirements.

♦ Industrial pump, fan, and compressor motors.

♦ Household appliance motors, such as air conditioners and washing machines.

♦ When selecting DMD insulation paper, consider the following key parameters:

♦ Thickness: Select the appropriate thickness based on the motor voltage level and slot space.

♦ Heat resistance rating: Ensure the heat resistance rating (such as F or H) matches the motor’s design temperature rise.

♦ Basis weight: Affects the material’s mechanical strength and insulation performance.

♦ Certification: Choose products with international certifications such as UL and CE to ensure material quality and safety.

As motors continue to evolve toward higher efficiency, smaller size, and greater reliability, selecting insulation materials with excellent overall performance is crucial. DMD insulation paper, with its high mechanical strength, stable insulation properties, excellent heat resistance, and ease of processing, meets the stringent requirements of modern motors. Whether designing and manufacturing new motors or maintaining and upgrading existing ones, DMD insulation paper is a reliable choice for long-term, stable operation.

Contact a professional insulation material supplier to find the most suitable DMD insulation paper solution for your motor and enhance your product’s overall competitiveness!

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……