DMD prepreg—often referred to as epoxy prepreg DMD or F-class prepreg DMD—is a flexible composite material made from polyester film and polyester fiber non-woven fabric. It is impregnated with epoxy resin and then baked to form a stable prepreg product.

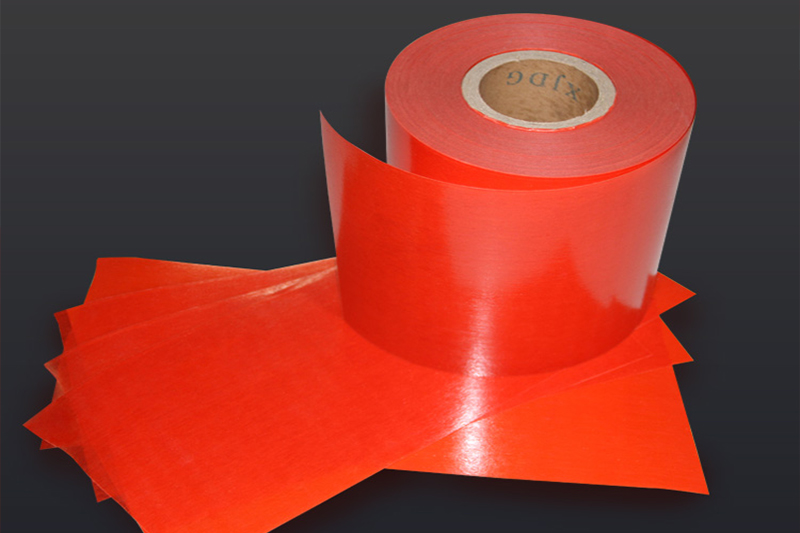

This material offers excellent electrical properties, thermal resistance, and flame-retardant performance. It can be stored for long periods at room temperature. Its appearance is smooth and uniform in thickness, free from impurities, creases, bubbles, wrinkles, or holes. The material is soft and does not block or stick together during unwinding.

DMD prepreg can be cured under different temperature and time settings. This flexibility greatly facilitates the manufacturing process of dry-type transformers.

After curing, DMD prepreg forms an insulating structure with extremely low shrinkage, helping ensure long-term stability and reliability of the transformer’s insulation system.

DMD prepreg has outstanding adhesion to copper foil, aluminum foil, and other conductive materials. It ensures tight bonding between the insulation layer and the windings without gaps.

During the curing reaction, DMD prepreg produces almost no low-molecular volatile substances. This feature is environmentally friendly and ensures production and usage safety.

The primary function of a dry-type transformer is voltage transformation, during which extremely high potential differences exist between windings and between turns. The polyester film layer in F-class prepreg DMD insulation paper offers exceptionally high dielectric strength and insulation resistance. This film layer effectively prevents inter-turn short circuits, avoids main insulation breakdown, and ensures the safe electrical operation of the transformer.

During transformer operation—especially under short-circuit current impact—the windings are subjected to significant electromagnetic forces. The upper and lower layers of polyester fiber non-woven fabric in DMD insulation paper provide excellent mechanical toughness, tear resistance, and puncture resistance. After resin impregnation and hot-press curing, the insulation paper bonds tightly with the copper conductors, significantly improving the transformer’s short-circuit withstand capability.

Prepreg DMD insulation paper is an F-class insulating material with a thermal endurance rating of 155°C. It can withstand high temperatures generated during overload operation without rapid aging, carbonization, or loss of insulation performance. This thermal stability extends the service life of the transformer and supports the development of dry-type transformers with higher power density and more compact designs.

F-class prepreg DMD insulation paper is primarily used in the manufacturing of dry-type transformer coils. It serves as a key inter-turn, inter-layer, and structural insulation material during the production process. Its main application scenarios include:

Prepreg DMD insulation paper is wrapped around each flat or round copper conductor. It isolates adjacent conductors and prevents inter-turn short circuits.

Prepreg DMD insulation paper is placed between different layers of the winding. This prevents insulation breakdown between coil layers with different electrical potentials.

It is used as a spacer between the winding and the core, as well as between the high-voltage and low-voltage windings. This enhances the overall insulation performance of the transformer.

DMD prepreg should be stored below 30°C in a dry, clean, and well-ventilated warehouse. It must be kept away from fire sources, heat sources, and direct sunlight. The standard storage period is one year. After this period, it can still be used if it passes inspection. During use, appropriate curing parameters should be selected according to specific process requirements to ensure the quality and performance of the insulation layer.

F-class prepreg DMD insulation paper is a key technical support material that enables dry-type transformers to achieve high efficiency, safety, reliability, and long service life. Combining electrical insulation, mechanical reinforcement, and thermal protection, it represents a typical example of how advanced materials science is applied in modern power equipment engineering.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……