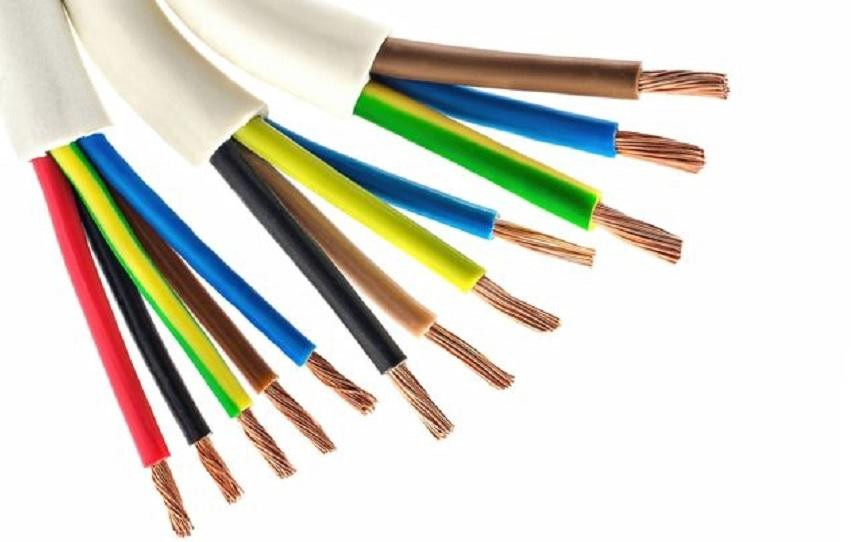

When it comes to cable applications, selecting insulation materials that meet industry standards is essential. The right insulation material not only protects cables from external factors but also ensures optimal performance and safety. In this blog post, we will explore expert-recommended insulation materials that comply with industry standards, including glass fiber, rubber insulation, silicone, nylon, and more.

Glass fiber insulation is known for its excellent thermal resistance and high mechanical strength. It is commonly used in high-temperature cable applications where other insulation materials may fail. Glass fiber insulation provides exceptional fire resistance and is compliant with industry standards such as UL 1446 and IEC 60684.

Rubber insulation offers excellent electrical properties and flexibility, making it suitable for a wide range of cable applications. It provides good resistance to moisture, chemicals, and abrasion. Rubber insulation is commonly used in low-voltage cables and meets industry standards such as UL 44 and IEC 60245.

Silicone offers excellent thermal stability, allowing it to withstand high temperatures without degradation. It also possesses good electrical insulation properties and is resistant to moisture, chemicals, and UV radiation. Additionally, silicone insulation exhibits high flexibility, making it suitable for applications that require bending or movement. However, silicone may have a higher cost compared to other insulation materials.

Nylon insulation, also known as polyamide, is renowned for its exceptional mechanical strength and resistance to abrasion. This makes it an ideal choice for cable applications in demanding environments where friction or wear is a concern. Nylon insulation finds widespread use in automotive, industrial, and consumer electronics sectors, thanks to its reliable performance. It meets industry standards such as UL 758 and IEC 60317.However, it is important to note that nylon insulation may have a limitation in terms of its waterproofing capability.

PE is an affordable, versatile choice. It has higher density and hardness than PVC, excellent electrical insulation, and resists cracking at temperatures from -65°C to 80°C. PE is commonly used in coaxial and low-capacitance cables, ideal for high-speed transmission.

PVC insulation for cables offers excellent electrical performance, including high insulation resistance and good dielectric strength. It is flame retardant, self-extinguishing, and resistant to moisture, chemicals, and abrasion. PVC insulation is widely used in cable applications due to its reliable performance and compliance with industry standards.It complies with industry standards such as UL 758, IEC 60227, and IEC 60502.

XLPE is a popular cable insulation material known for its excellent electrical performance. It offers high insulation resistance, good dielectric strength, and superior heat resistance. XLPE is also resistant to moisture, chemicals, and abrasion, making it suitable for a wide range of cable applications. It complies with industry standards such as UL 758 and IEC 60502 and is widely used in power distribution and industrial cables.

EPR is a synthetic rubber insulation material that provides excellent electrical insulation properties. It has high dielectric strength, good resistance to moisture, and excellent thermal stability. EPR insulation is flexible and exhibits good mechanical strength, allowing for easy installation and handling. It complies with industry standards such as UL 44, IEC 60502, and IEEE 383.

Semi-rigid PVC insulation offers a balance between flexibility and rigidity. It provides good electrical insulation properties and is commonly used in applications where mechanical strength is required. Semi-rigid PVC insulation is resistant to moisture, chemicals, and UV radiation. It meets industry standards such as UL 758 and IEC 60502.

PTFE insulation is known for its excellent electrical properties, including a high dielectric strength and low dielectric constant. PTFE insulation is commonly used in high-frequency signal transmission cables and meets industry standards such as UL 758 and IEC 60684.

CSPE insulation, also known as Hypalon, is a synthetic rubber material that provides excellent resistance to chemicals, abrasion, and UV radiation. It offers good electrical insulation properties and is commonly used in harsh environments where durability is crucial. CSPE insulation complies with industry standards such as UL 44 and IEC 60092.

TPR insulation combines the properties of rubber and plastic, offering good flexibility and mechanical strength. It provides excellent resistance to heat, chemicals, and UV radiation. TPR insulation is commonly used in cables requiring flexibility and durability. It meets industry standards such as UL 758 and IEC 60502.

FEP insulation offers excellent electrical properties, high thermal stability, and resistance to chemicals. It is commonly used in high-temperature applications, such as aerospace and automotive industries. FEP insulation provides good flexibility and meets industry standards such as UL 758 and IEC 60502.

Neoprene insulation is a synthetic rubber material known for its excellent resistance to chemicals, oils, and abrasion. It provides good electrical insulation properties and is commonly used in cables requiring resistance to harsh environments. Neoprene insulation complies with industry standards such as UL 44 and IEC 60092.

SBR insulation, also known as synthetic rubber, offers good electrical insulation properties and flexibility. It provides resistance to abrasion and is commonly used in low-voltage applications. SBR insulation meets industry standards such as UL 44 and IEC 60245.

Fluoropolymer insulation, such as FEP (fluorinated ethylene propylene) and PFA (perfluoroalkoxy), offers exceptional electrical properties, high thermal stability, and resistance to chemicals. These insulation materials are commonly used in high-performance applications where extreme temperature and chemical resistance are required. Fluoropolymer insulation meets industry standards such as UL 758 and IEC 60502.

TPE insulation combines the properties of thermoplastics and elastomers, offering flexibility, good mechanical strength, and resistance to environmental factors. It provides excellent electrical insulation properties and is commonly used in cables requiring flexibility and durability. TPE insulation meets industry standards such as UL 758 and IEC 60502.

Polyurethane insulation offers excellent mechanical strength, flexibility, and resistance to abrasion. It provides good electrical insulation properties and is commonly used in demanding cable applications. Polyurethane insulation is resistant to chemicals and UV radiation, making it suitable for both indoor and outdoor use. It complies with industry standards such as UL 758 and IEC 60502.

EVA insulation is known for its flexibility, good electrical insulation properties, and resistance to impact. It offers excellent thermal stability and is commonly used in low-voltage cable applications. EVA insulation meets industry standards such as UL 44 and IEC 60227.

ECTFE insulation, also known as Halar, offers exceptional resistance to chemicals, heat, and flames. It provides good electrical insulation properties and is commonly used in high-performance cable applications. ECTFE insulation meets industry standards such as UL 758 and IEC 60502.

Polyimide insulation is known for its excellent thermal stability, high dielectric strength, and resistance to chemicals. It is commonly used in high-temperature cable applications, such as aerospace and military sectors. Polyimide insulation complies with industry standards such as UL 1441 and IEC 60684.

ETFE insulation offers excellent resistance to chemicals, UV radiation, and extreme temperatures. It provides good electrical insulation properties and is commonly used in harsh environments. ETFE insulation meets industry standards such as UL 758 and IEC 60502.

Polypropylene insulation offers good electrical insulation properties and resistance to moisture, chemicals, and UV radiation. It is commonly used in low-voltage cable applications. Polypropylene insulation complies with industry standards such as UL 44 and IEC 60227.

EVA/PE insulation combines the properties of EVA and PE, offering flexibility, good electrical insulation properties, and resistance to moisture and chemicals. It is commonly used in low-voltage cable applications. EVA/PE insulation meets industry standards such as UL 44 and IEC 60227.

TSE insulation combines the properties of thermosetting materials and elastomers, offering flexibility, resilience, and resistance to heat and chemicals. It provides good electrical insulation properties and is commonly used in cable applications requiring durability. TSE insulation complies with industry standards such as UL 44 and IEC 60502.

Choosing the right insulation material for cable applications is crucial to ensure compliance with industry standards and optimal performance. The materials recommended above are in accordance with industry standards. Cable manufacturers should consider specific application requirements and consult industry experts. We have our own factory and R&D team, offering free consultation services to assist you in selecting the appropriate insulation material. Feel free to reach out to us for any inquiries.

Email:ztelec@ztelecgroup.com Whatsapp:+8616650273775

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……