In the fields of power equipment, electronics, and advanced manufacturing, electrical insulation paperboard is a widely used and highly stable core insulation material. As application scenarios expand and equipment structures become more sophisticated, customized insulation paperboard has become the mainstream choice for many enterprises. This article provides a comprehensive overview of the advantages, common types, application scenarios, and supplier selection criteria for customized insulation paperboard processing, helping companies enhance project safety and execution efficiency.

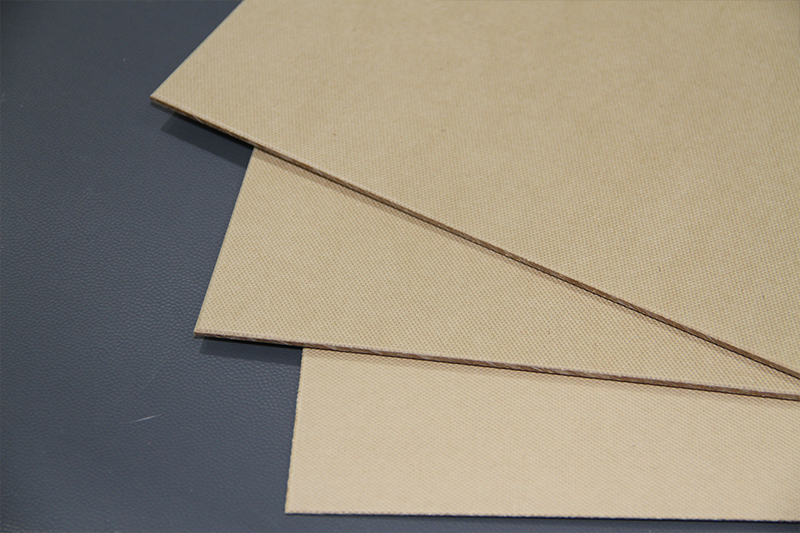

Electrical insulation paperboard is made from plant fibers, pulp, or composite fibers, produced through processes such as pressing, drying, and resin impregnation. Its key functions include electrical insulation, mechanical support, and thermal stability. It is mainly used in:

Transformers (oil-immersed and dry-type)

Motors and generators

Power capacitors

High- and low-voltage electrical equipment

New energy equipment (energy storage systems, electric vehicles)

Each electrical engineering project has unique design parameters and environmental conditions. Customized processing ensures insulation components perfectly match equipment structures, preventing installation issues or performance risks caused by mismatched dimensions.

Custom processing helps reduce material waste. For small batches or special specifications, customization is more cost-effective than purchasing standard parts and performing secondary processing.

Professional processes—such as precision punching, laser cutting, and layered lamination—significantly improve the mechanical strength, electrical performance, and durability of insulation components.

Customized processing providers often offer one-stop services from design consultation to final delivery. This streamlines the customer’s supply chain and speeds up product time-to-market.

Professional customization suppliers have solid material expertise and extensive application experience. They can provide technical recommendations and collaborate with customers to develop innovative solutions.

According to different project requirements, common customized processing forms include:

Motor slot wedges and slot liners

Transformer blocks, barriers, and pressure rings

Capacitor insulation boards

C-shaped, U-shaped, and L-shaped special-shaped parts

Laminated high-density insulation boards (such as DDP and DMD matching paperboards)

Laser-cut precision insulation components

Transformer manufacturing: Coil insulation, interlayer insulation, end insulation components

High-voltage switchgear: Insulation barriers, supporting components, arc-control parts

Motors and electrical appliances: Slot insulation, phase-to-phase insulation, padding materials

New energy equipment: PV inverters, wind power converters, charging pile insulation components

A qualified supplier must be familiar with the characteristics of various insulation paperboards such as DDP, DHP, and T4, and be able to recommend suitable base materials based on the application environment.

The supplier should be equipped with advanced equipment such as CNC cutting, laser processing, and hydraulic punching, supported by a strict quality control system.

An excellent supplier can provide technical consultation from the design stage and assist in optimizing insulation structure solutions.

The supplier should be familiar with and compliant with industry standards such as IEC, UL, and GB. And products have undergone required testing and certification.

For urgent needs or design changes, the supplier should have rapid response capabilities and flexible production adjustment mechanisms.

In modern power equipment and industrial manufacturing, customized electrical insulation paperboard has become a key approach to improving equipment safety, reliability, and efficiency. By selecting suitable insulation materials and a professional custom processing manufacturer, enterprises can not only meet diverse design requirements but also enhance product quality and core competitiveness in the market.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……