In reactor systems such as nuclear power, chemical reactors, and high-end scientific research facilities, equipment needs to operate for extended periods under high temperature, high voltage, high mechanical stress, and complex media environments. This places extremely high demands on the material properties of structural and insulating components within the equipment. Epoxy machined parts, with their excellent electrical insulation properties, mechanical strength, and dimensional stability, have become an indispensable material in reactors.

This article systematically introduces the main application scenarios, performance advantages, selection criteria, and development trends of epoxy machined parts in reactors, providing a reference for equipment design and material selection.

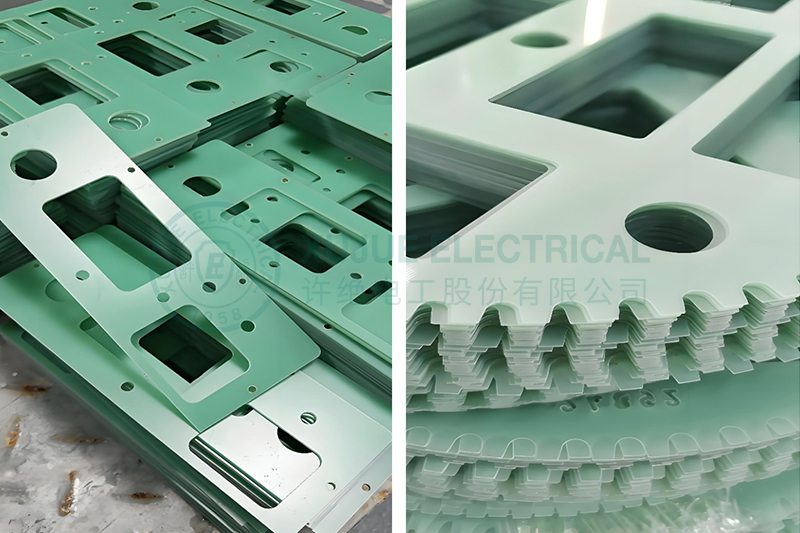

Epoxy machined parts are customized parts made from epoxy resin laminates or glass fiber reinforced epoxy materials (such as G10, G11, FR4, etc.) as the base material, through CNC machining, precision cutting, drilling, milling, and other processes.

Their typical characteristics are as follows:

High dielectric strength and excellent insulation reliability

Good heat resistance and thermal stability

Excellent mechanical strength and impact resistance

High machinability, adaptable to complex structural designs

Inside the reactor, epoxy machined parts are used to support conductive parts, coils, electrodes, and busbar structures. They provide reliable electrical isolation while achieving mechanical fixation, mitigating creepage and short-circuit risks. Common forms:

Insulating brackets

Insulating columns

Composite support frames

Some areas of the reactor are in a continuously high-temperature environment, requiring materials with stringent heat resistance standards. High-temperature resistant epoxy machined parts such as G11 can be used as insulating parts, structural pads, and spacing maintainers, effectively preventing current leakage, uncontrolled heat conduction, and structural deformation.

In high-voltage reactors or electrically heated reaction systems, epoxy machined parts are widely used in high-voltage insulating covers, end insulating protection components, and cable outlet insulating flanges. Their high dielectric strength and partial discharge resistance enhance the overall safety level of the system.

In chemical reactors or special experimental reaction devices, epoxy machined parts can withstand certain levels of acids, alkalis, oils, and various chemical media. They are suitable for internal fixed structures, insulating protective linings, and auxiliary support components.

In practical engineering applications, the following factors should be carefully considered when selecting epoxy machined components:

♦ Operating temperature and continuous service duration

♦ Voltage level and insulation safety margin

♦ Mechanical loads and installation methods

♦ Exposure to chemical media and radiation environments

♦ Machining precision and structural complexity

♦ Proper material selection and standardized machining processes are critical to ensuring the safe and stable operation of reactors.

The designs of Small Modular Reactors (SMRs) and Generation IV reactors are creating new application scenarios for epoxy machined components, moving toward more integrated and modular solutions.

Development of self-healing epoxy systems

Research into nano-reinforced epoxy composite materials

Development of intelligent epoxy materials with integrated sensing functions

Recyclable epoxy resin systems and low–environmental-impact manufacturing processes have become key focuses of industry research and development.

The application of epoxy machined components in nuclear reactors has evolved from auxiliary parts to critical safety components. Their unique combination of properties provides reactor designers with solutions that traditional materials cannot achieve. With ongoing advances in materials science and nuclear technology, epoxy machined components will play an increasingly important role in ensuring reactor safety, improving operational efficiency, and extending service life.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……