In modern industrial production, copper foil core tubes have become an indispensable key component in many fields due to their unique performance advantages. So, in what application scenarios are copper foil core tubes commonly used? This article will explore in depth its specific applications and advantages in the electronics industry, new energy field and aerospace field.

In the electronics industry, FRP core tubes play a vital role and are mainly used in the winding process of conductive materials and film materials.

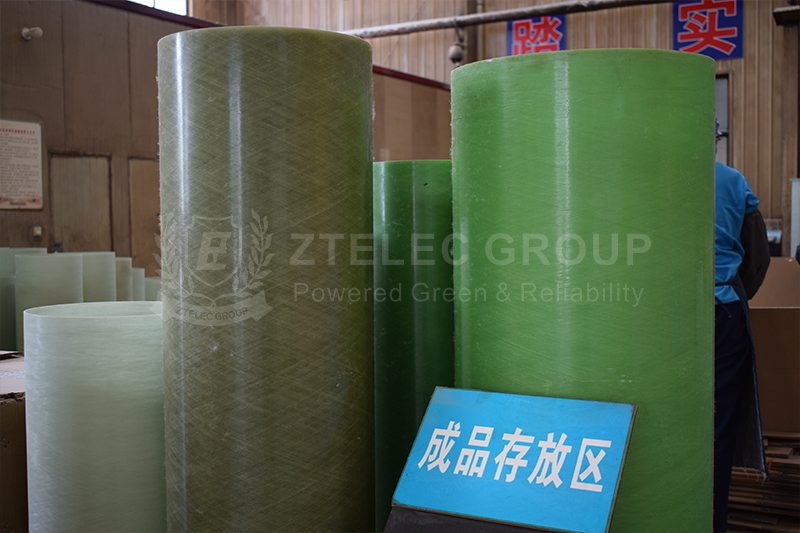

FRP core tubes are widely used in the winding operation of conductive materials such as copper foil and aluminum foil. Its excellent roundness and straightness provide stable and precise guarantees for the winding process, thereby effectively improving the manufacturing quality of electronic components. In the production of electronic components, the winding accuracy of conductive materials directly affects the subsequent processing and product performance. The application of copper foil tubes ensures the high-quality winding of conductive materials.

Various film materials, such as polyimide film, polyester film, etc., are used in the electronics industry to manufacture flexible circuit boards, insulation materials, etc., and FRP tubes are ideal for winding these films. In the process of flexible circuit board manufacturing, the flat winding and storage of the film have a significant impact on the quality and performance of the circuit board, and copper foil tubes can meet this demand.

High dimensional accuracy: FRP tubes have excellent roundness and straightness, and the surface finish is also very high. This feature not only helps to increase the utilization rate of film and copper foil, but also significantly reduces the material loss caused by surface roughness and reduces production costs.

High strength and rigidity: The tube can withstand a large weight without deformation, providing stable and safe support for the material during the winding process, ensuring the smooth progress of the production process.

Strong corrosion resistance: Many materials in the electronics industry have strict environmental requirements. The good corrosion resistance of copper foil tubes enables them to resist the erosion of chemical substances such as acids and alkalis, effectively extending their service life and reducing the frequency of replacement.

The new energy field is another important application scenario for the FRP tube, which can be seen in the manufacture of lithium batteries and solar cells.

In the manufacturing process of lithium batteries, FRP tubes are used as winding tubes for key materials such as diaphragms and copper foils. Its light weight and high strength characteristics enable lithium batteries to effectively reduce weight while maintaining high performance, thereby increasing energy density. This advantage is particularly important in application scenarios such as new energy vehicles that require high battery weight and performance.

In the production process of solar panels, FRP tubes are used to wind and store various materials such as silicon wafers and backplanes. In the large-scale production of solar panels, the orderly winding and storage of materials have a direct impact on production efficiency and product quality, and the application of copper foil tubes provides a reliable guarantee for it.

Lightweight and high strength: This feature of FRP core tube makes new energy products lighter and more efficient, which is in line with the development trend of the new energy industry to pursue high efficiency and low energy consumption.

Strong insulation performance: In the field of new energy, insulation performance is a factor that must be considered. The good insulation performance of FRP core tube provides a strong guarantee for the safe operation of new energy products and reduces safety hazards.

In the field of aerospace, weight is one of the key considerations. FRP core tube is widely used in the manufacture of various lightweight structural parts, such as ducts, brackets, etc. due to its light weight and high strength. Reducing the weight of structural parts helps to improve the fuel efficiency and flight performance of aircraft.

FRP core tube can also be used as a mold or core material for composite material manufacturing to manufacture more complex aerospace parts. By applying copper foil core tube to composite material manufacturing, aerospace parts with better performance and lighter weight can be produced to meet the high-end needs of the industry.

Light weight: This feature makes aerospace products lighter, which can reduce the overall weight of the aircraft and improve flight efficiency while ensuring performance.

High strength: Copper foil core tubes have high strength and rigidity. So it can withstand various complex loads in the aerospace field, ensuring the stability and reliability of components in harsh environments.

Copper foil core tubes have wide and important applications in the electronics industry, new energy field and aerospace field due to their advantages such as high dimensional accuracy, strong strength and rigidity, and light insulation. With the continuous development of various industries, their application prospects will be broader.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……