Insulating paperboard is a key insulation material used in power equipment, electronic components, and industrial machinery. Its performance directly determines the safe operation and service life of equipment. This article provides an in-depth analysis of the core international and domestic standards for insulating paperboard, helping you fully understand the technical specifications of this material.

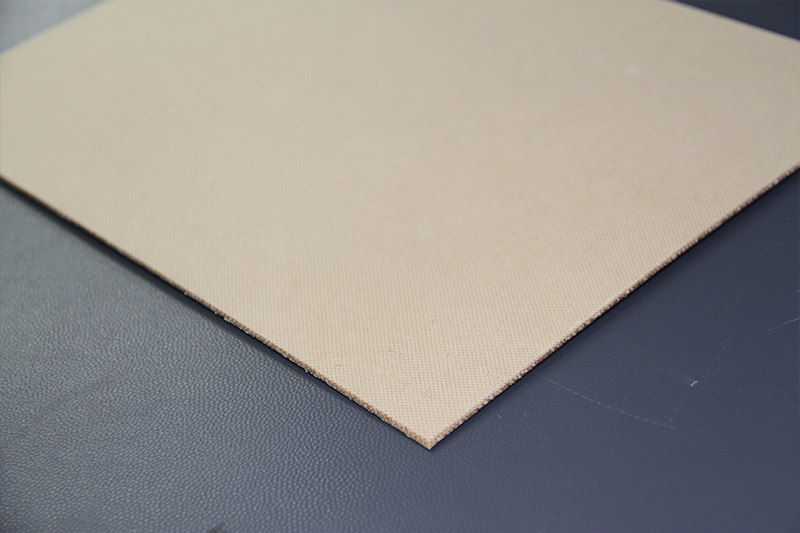

Insulating paperboard is a rigid or flexible sheet insulation material made from pure wood pulp or synthetic fibers. It offers excellent electrical insulation, mechanical strength, and heat resistance. According to application scenarios, it can be categorized as follows:

Transformer insulating paperboard

Motor slot insulating paperboard

Cable insulating paperboard

Insulating gaskets for electronic components

The standards system for insulating paperboard mainly includes international standards and Chinese national standards.

IEC 60216 series: Defines the thermal class and thermal aging characteristics of insulating materials.

IEC 60641 series: Specifies the testing methods for the mechanical and dielectric properties of electrical insulating paper and paperboard.

ASTM D787 / ASTM D150: Standards by the American Society for Testing and Materials. It is used to test the dielectric strength and volume resistivity of insulating paperboard.

GB/T 12706 series: Applicable to the selection and testing of insulating paperboard for transformers, reactors, and other power equipment.

GB/T 1409 series: Covers the performance indicators and testing methods for industrial polymer insulating paperboard.

The standards focus on the following core performance parameters:

♦ Dielectric strength: Measures the paperboard’s ability to withstand voltage

♦ Volume resistivity: A key parameter for evaluating the insulation effectiveness

♦ Moisture absorption: Directly affects the electrical performance and durability of the paperboard

♦ Mechanical strength: Determines the paperboard’s pressure resistance and load-bearing capacity

♦ Thermal class: Corresponds to the paperboard’s service life under different temperature conditions

It must comply with the stringent requirements of IEC 60641-3-2 and GB/T 19264, with key requirements as follows:

Extremely high uniformity of the paperboard

Strict limits on impurity content

Clear linear relationship between dielectric strength and board thickness

It must meet the requirements for tracking resistance index specified in IEC 62329.

Modern standards increasingly emphasize environmental performance, including:

Heavy metal content must comply with RoHS directive limits

Materials must meet recyclability requirements

Production processes must follow relevant environmental protection standards

Select the appropriate thermal class according to the equipment type (e.g., transformer, motor, capacitor) and operating temperature environment.

Prefer suppliers with third-party testing certification to ensure reliable product quality.

High-performance equipment requires insulating paperboard with low moisture absorption and high dielectric strength to ensure long-term stable operation.

Legitimate insulating paperboard products should provide:

Factory inspection reports

Type test reports (including full performance testing)

Third-party certification certificates

Material Safety Data Sheet (MSDS)

Prefer products that comply with IEC standards and are certified in major countries.

Choose the thermal class appropriate for actual application conditions to avoid overdesign.

Consider the supplier’s technical support capabilities and customization services.

Pay attention to batch consistency and quality stability of the material.

For critical applications, third-party testing verification is recommended.

Mastering the standards for insulating paperboard is the foundation for material selection and application. By familiarizing with international standards (IEC, ASTM) and Chinese national standards (GB/T series), and combining them with actual equipment requirements and performance indicators, the most suitable type of insulating paperboard for a project can be quickly determined.

In both power engineering and electronics manufacturing, standardized insulating paperboard not only enhances equipment operational safety but also reduces maintenance costs, achieving an optimal balance of economy and performance.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……