G11 epoxy board is a high-performance glass fiber reinforced epoxy resin laminate. It has a high temperature resistance rating of Class F (150℃), high mechanical strength, and good insulation properties. It is commonly used in motors, transformers, power equipment, electronic structural components, and other fields. Some users are concerned: Is G11 epoxy board toxic? Will it release harmful substances during use?

This article provides a comprehensive analysis from the aspects of material composition, safety, environmental standards, and typical applications.

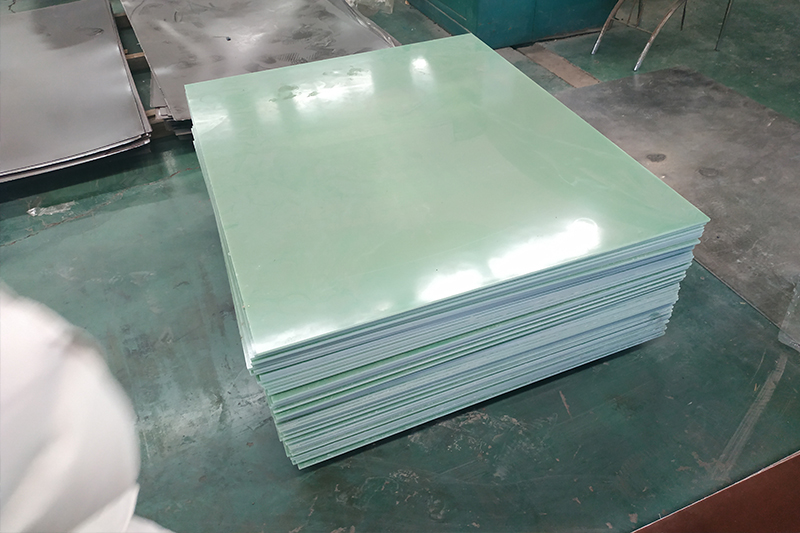

G11 epoxy board belongs to a grade in the NEMA standard. The main components of G11 epoxy board are:

♦ Epoxy resin: As a binder, commonly bisphenol A type epoxy resin

♦ Glass fiber: As a reinforcing material, providing mechanical strength

♦ Curing agent: Such as amine compounds

♦ Additives: May contain flame retardants, colorants, etc.

The cured epoxy resin is a stable polymer material that meets the safety requirements of the electrical insulation industry.

Under normal temperature and operating conditions:

– No gas release

– No volatile organic compounds (VOCs) produced

– No toxicity to humans

Therefore, G11 is a safe, environmentally friendly, and reliable insulating material.

G11 epoxy boards typically meet the following standards:

UL 94: Flame retardant rating (usually V-0)

RoHS: Restriction of Hazardous Substances Directive

REACH: Registration, Evaluation, and Licensing of Chemicals

NEMA Standard: Electrical Insulation Standard

The risks primarily lie in the processing:

Incompletely cured substances: Incompletely cured epoxy resin during production may release small amounts of volatile organic compounds (VOCs).

Processing dust: Glass fiber and resin dust generated during cutting and grinding may irritate the respiratory tract and skin.

Thermal decomposition products: Decomposition at extremely high temperatures (far exceeding normal operating temperatures) may produce harmful gases.

Personal Protective Equipment (PPE):

Dust mask (NIOSH N95 or higher)

Safety goggles

Protective gloves

Long-sleeved work clothes

Environmental Controls:

Use local exhaust ventilation systems

Wet processing to reduce dust

Regularly clean work areas

Avoid high-temperature decomposition: Do not use in environments exceeding the material’s rated temperature.

Avoid open flames: Although G11 epoxy boards are flame-retardant, direct combustion will produce toxic fumes.

Food and Medical Application Restrictions: Generally, it is not used directly in food contact or for implantable medical devices.

G11 epoxy board is widely used due to its high temperature resistance, high bending strength, and stable electrical properties:

Motor slot wedges

End rings

Insulation supports

Pressure plates, motor rings

Laminated pads

Insulation boards

Support components

SMT reflow soldering carriers

High-temperature fixtures

IC test fixtures

Q1: Does G11 epoxy board release formaldehyde?

Normal cured G11 epoxy board does not actively release formaldehyde. However, it may produce formaldehyde-containing decomposition products during high-temperature decomposition or combustion.

Q2: Is epoxy board safe in household appliances?

Fully cured epoxy board is safe under normal operating conditions of electrical appliances. It has been widely used in household appliances for decades.

Q3: How to safely dispose of waste epoxy board?

It is recommended to treat it as industrial solid waste. Incineration should be carried out in a location with flue gas treatment facilities to avoid open-air burning.

G11 epoxy boards, when fully cured and used correctly, are safe and reliable high-performance engineering materials. The main risks lie in the dust generated during processing and the decomposition products at extreme temperatures. By taking appropriate protective measures and adhering to operating procedures, their performance can be safely utilized.

Choosing products from reputable manufacturers that meet international standards and following safety guidelines during processing and use are crucial for ensuring the safe application of G11 epoxy boards.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……