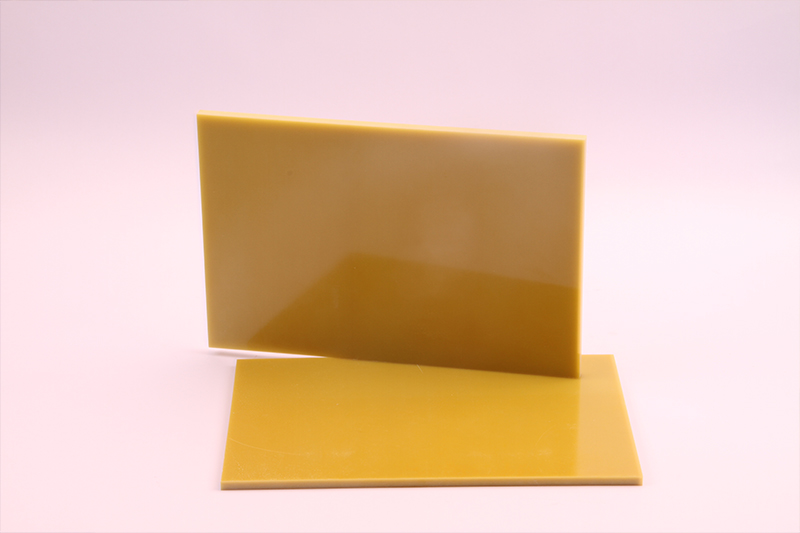

3240 epoxy fiberglass sheet (also known as FR-4 epoxy sheet) is a widely trusted material for electrical insulation, mechanical support, and structural applications. Its excellent electrical properties, mechanical strength, and heat resistance make it a top choice for a wide range of applications, from distribution boxes to electronic equipment chassis. However, project success often hinges on one key factor: choosing the right sheet thickness.

Incorrect thickness selection can lead to equipment failure, safety hazards, or increased costs. This guide systematically explains how to select the optimal 3240 epoxy fiberglass sheet thickness based on specific application requirements to achieve the optimal balance of performance, safety, and cost-effectiveness.

3240 epoxy fiberglass sheet is a composite material made from electronic-grade fiberglass cloth impregnated with epoxy resin and thermoset under high temperature and pressure. It offers excellent mechanical strength, high rigidity, superior insulation properties, and good chemical and heat resistance, with a long-term operating temperature exceeding 120°C.

• For applications that bear weight or are subject to significant mechanical forces, such as transformer partitions, motor slot wedges, and support gaskets, thicker gauges, such as 10mm, 20mm, or even thicker, should be selected.

• For applications such as circuit board substrates or lightweight structures, thinner gauges, such as 0.5mm, 1.0mm, or 1.5mm, are commonly used.

• Summary: The greater the stress, the greater the thickness.

• When 3240 epoxy fiberglass board is used in high-voltage environments such as switchgear and distribution boards, a thickness of 3mm or greater is typically selected to prevent high-voltage breakdown.

• When used in ordinary low-voltage circuits, a thickness of 1mm–2mm is generally sufficient.

• In confined spaces such as mobile phones and portable devices, ultra-thin 3240 epoxy fiberglass board, such as 0.1mm and 0.2mm, is often used.

• In applications with ample space, such as industrial cabinets, the thickness can be selected primarily based on stress and voltage.

• 3240 epoxy fiberglass sheets thicker than 1.5mm are easier to handle during CNC machining or drilling. Thinner sheets are more susceptible to damage.

• If bending is required, select specific thin sheets and control the bending radius.

• When using bolts for fastening, the sheet thickness should be greater than the bolt diameter to ensure strong fastening.

Assuming the required specifications are met, choose thinner sheets to help save material costs.

The following are thickness recommendations for some typical application scenarios (for reference only; specific thicknesses should be determined based on project design):

PCB substrates: 0.8mm, 1.0mm, and 1.6mm are the most common standard thicknesses.

Electrical equipment insulation gaskets/shims: 1.0mm to 3.0mm. Fine-tune based on voltage and mechanical strength requirements.

Transformer insulation bobbins/partitions: 2.0mm to 5.0mm. It requires excellent structural strength and insulation.

Motor and generator slot wedges: 2.0mm to 6.0mm. It requires high mechanical strength and wear resistance.

Test fixtures/tooling bases: 10mm to 30mm. It requires extremely high rigidity and flatness to maintain measurement accuracy.

High-voltage switchgear insulation components: 5mm and above. It ensures sufficient safe insulation distance and mechanical strength.

Define your requirements: List all application requirements regarding mechanical load, voltage level, space dimensions, processing methods, and budget.

Consult with suppliers: Submit your requirements to a professional 3240 epoxy board supplier. They are experienced and can provide recommendations and relevant technical data sheets, including UL certification, flame retardancy rating, and mechanical properties.

Request samples: Before purchasing in bulk, request samples of the intended thickness from the supplier. Perform actual processing tests on the samples, such as drilling and cutting. Also perform simple performance verification, such as measuring dimensions and checking flatness.

Final Verification: Determine the most appropriate thickness specification based on the sample test results and the supplier’s recommendations.

Selecting the appropriate 3240 epoxy fiberglass board thickness for your project requires a comprehensive consideration of many factors. There is no one-size-fits-all solution, and only a suitable solution that meets the specific application needs. By thoroughly evaluating your mechanical, electrical, space, and processing requirements and collaborating with professional suppliers, you can determine the appropriate procurement solution to ensure a stable, safe, and efficient project.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……