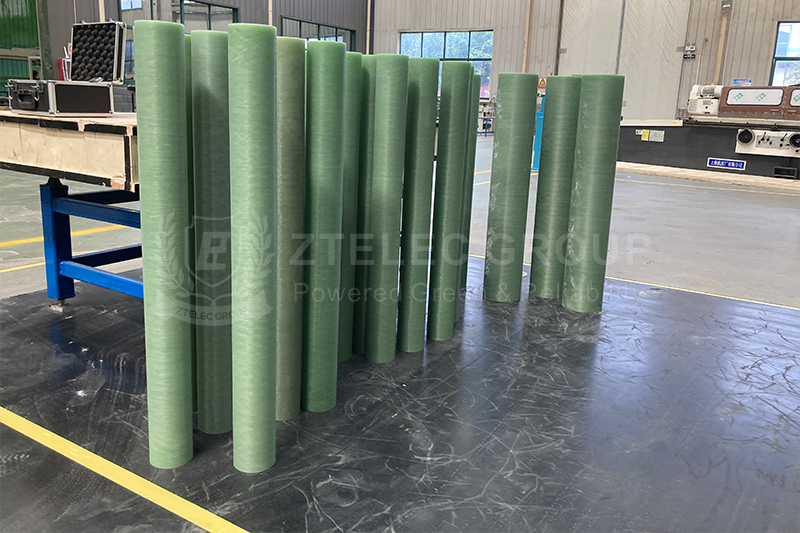

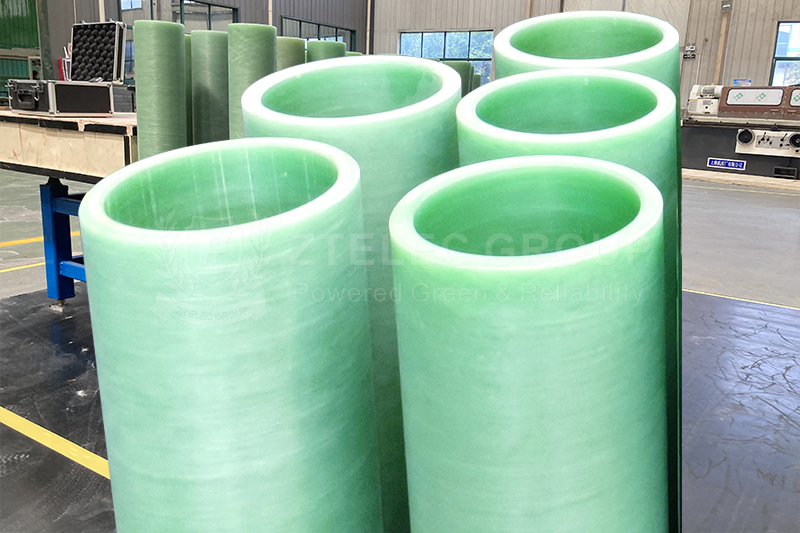

In the quality control system of copper foil tube, what does the environmental protection requirement specifically cover? As the core component of the copper foil winding process, the FRP copper foil tube directly affects the stability and product quality of the copper foil from production, storage to transportation. With the popularization of environmental protection concepts and the increasingly sound laws and regulations, the environmental protection standards in its quality control are becoming increasingly stringent. Strict implementation of these requirements is not only a reflection of the company’s practice of social responsibility, but also the key to the product’s market recognition.

Epoxy resins, unsaturated polyester resins, etc. are commonly used resins for FRP copper foil core tubes. However, they may release VOCs during the curing process. Therefore, environmental protection standards have clear restrictions on the VOCs content in resins. Using resins with low VOCs content can effectively reduce harmful gas emissions during the production process and improve the air quality of the working environment.

From the perspective of sustainable development, resin materials should be recyclable or biodegradable. After the product is discarded, recyclable resin can be reprocessed and reused through specific processes to reduce resource waste.

The mining and processing of raw materials for reinforcing fibers such as glass fiber and carbon fiber must comply with environmental protection standards. Taking glass fiber as an example, the mining of minerals such as quartz sand should follow the principle of sustainability to prevent excessive mining from leading to resource depletion and ecological damage, and at the same time do a good job in soil and water conservation and ecological restoration.

The production of reinforced fibers should strictly control pollutant emissions. When melting glass fiber, it is necessary to control the emission of waste gases such as sulfur dioxide and nitrogen oxides, and use advanced processes and treatment equipment to ensure compliance. Production wastewater must also be recycled or discharged in compliance after treatment to avoid polluting water resources.

Enterprises need to formulate clear unit product energy consumption standards and strictly control the use of energy in the production of FRP tubes. For example, it is stipulated that the upper limit of electricity, heat energy, etc. is set for each tube produced for a certain length, and energy consumption is reduced by optimizing the process and using energy-saving equipment, such as high-efficiency curing furnaces.

Improving energy utilization is an important direction for production environmental protection. Enterprises can use waste heat recovery technology to use production waste heat for raw material preheating or other links, and at the same time reasonably plan the process to reduce energy transmission and conversion losses.

Production waste gas mainly comes from volatile gases generated by resin curing and fiber processing dust. Enterprises need to install activated carbon adsorption, catalytic combustion and other treatment equipment to ensure that waste gas emissions meet standards.

Production wastewater generated by equipment cleaning, cooling, etc. must undergo sedimentation, filtration, biochemical and other treatment processes to meet national emission standards before being discharged. At the same time, enterprises are encouraged to achieve zero wastewater discharge or recycling.

Solid waste such as scraps, waste slag, and waste packaging materials should be collected and reused if they are recyclable. For example, glass fiber scraps can be processed into chopped fibers for other composite materials. Non-recyclable ones must be entrusted to professional units for safe disposal to prevent environmental pollution.

FRP copper foil tubes must not release harmful chemicals when in use to avoid contaminating the copper foil and the surrounding environment. For example, plasticizers and curing agents in the resin must be prevented from migrating to the copper foil and affecting its performance.

By optimizing the material formula and production process, the wear resistance, corrosion resistance and aging resistance of the tube can be improved, the durability and stability of the product can be enhanced, and the waste generated by frequent replacement can be reduced.

FRP copper foil core tubes should be highly recyclable and reusable. After being discarded, different materials can be recycled through disassembly, crushing, separation and other processes to achieve resource circulation.

The parts that cannot be recycled must be treated in an environmentally friendly manner, such as incineration equipped with efficient exhaust gas treatment equipment, or landfill that meets environmental standards, and highly polluting treatment methods must be eliminated.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……