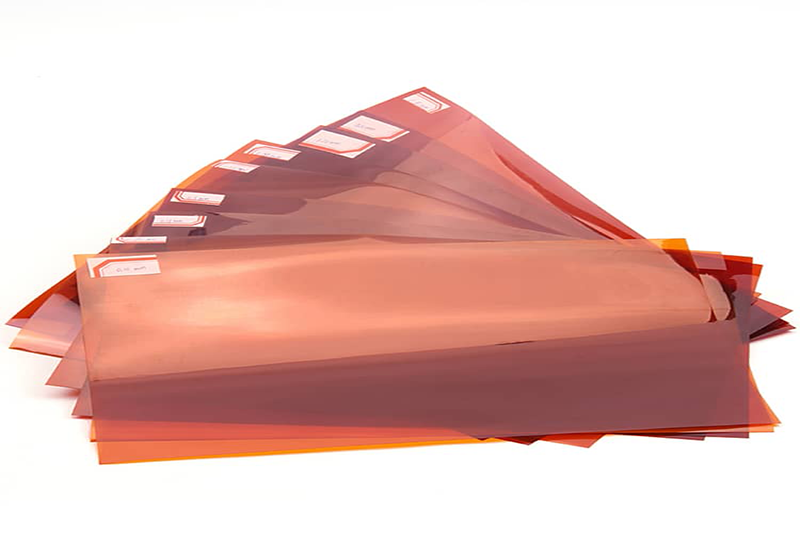

The continuous development of materials science in today’s high-tech field has provided more advanced solutions for various industries. Among them, Polyimide Film 6050 is highly favored in the electronics, aerospace, and other fields for its excellent thermal stability and electrical insulation performance. This article will delve into the characteristics, application areas, and role of Polyimide Film 6050 in technological innovation.

Polyimide Film 6050 is a type of polyimide film, with its base material being polyimide resin. This resin is renowned for its outstanding high temperature stability and chemical inertness.

1.Excellent thermal stability: Polyimide Film 6050 can maintain stability under extreme temperatures, making it suitable for high-temperature environments.

2.Superior electrical insulation performance: This film has good electrical insulation, making it an ideal material for electronic devices and circuits.

3.Chemical inertness: Its resistance to chemicals allows it to perform well in harsh working environments.

The production process of Polyimide Film 6050 utilizes advanced polymerization technology to ensure the uniformity and high quality of the film. This highly sophisticated manufacturing process lays the foundation for its excellent performance.

Polyimide Film 6050 is widely used in multiple fields due to its superior performance.

Electronics Industry

In the manufacturing of electronic devices, Polyimide Film 6050 is often used as the substrate for flexible printed circuit boards (FPCBs). Its flexibility and high temperature stability make it an indispensable part of mobile devices, computers, and other electronic products.

Aerospace

The aerospace industry has stringent requirements for materials, and Polyimide Film 6050 is widely used in aircraft, spacecraft, and other components due to its lightweight and high temperature resistance. For example, it can be used as a thermal insulation layer or electrical insulation material in spacecraft.

Medical Devices

In the manufacturing of medical devices, Polyimide Film 6050 is also used as a packaging material for flexible electronic devices to ensure stable operation in different environments.

The introduction of Polyimide Film 6050 has provided new possibilities for technological innovation in various fields.

The introduction of Polyimide Film 6050 has provided new possibilities for technological innovation in various fields.

Flexible Electronics Technology

With the rise of wearable devices and flexible electronics technology, the application of Polyimide Film 6050 as a flexible substrate has been greatly promoted. Its thinness and high temperature resistance enable the realization of bendable electronic devices.

High-Temperature Environment Applications

In high-temperature environments, many traditional materials fail, while Polyimide Film 6050’s thermal stability allows it to perform well under these extreme conditions. This provides a reliable material choice for various high-temperature environment applications, such as Mars rovers.

Polyimide Film 6050, as a high-performance polyimide film, plays an important role in the electronics, aerospace, medical, and other fields. Its superior thermal stability and electrical insulation performance make it an indispensable part of technological innovation. With the continuous progress of technology, Polyimide Film 6050 is expected to continue driving the advancement of various industries and opening up new possibilities for future technological innovation.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……