Magnetic conductive fiberglass sheets are extraordinary composite materials that possess remarkable properties. In this blog post, we will delve into the manufacturing process, applications, and storage guidelines of these sheets. Join us on this fascinating journey as we uncover the allure of magnetic conductive fiberglass sheets.

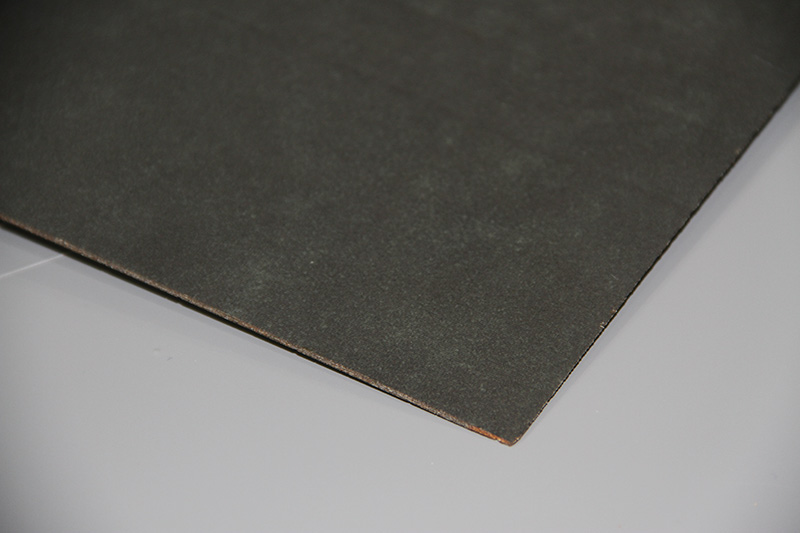

The magnetic conductive fiberglass sheet is meticulously fabricated using a lamination method. This involves the precise combination of raw materials in specific proportions. The ingredients include composite resin (100 parts by weight), amine curing agent (3 to 35 parts), curing accelerator (0.05 to 2 parts), soft magnetic material (370 to 400 parts), glass fiber cloth (60 to 100 parts), and antioxidant (0.7 to 1.5 parts). Through a careful process of sizing and pressing, the pre-cured sheets are transformed into the ultimate magnetic conductive sheets.

The enchanting features of magnetic conductive fiberglass sheets make them an indispensable material in various industries. With their high magnetic permeability, excellent mechanical properties, and longevity, these sheets have revolutionized the manufacturing of magnetic wedges for motors. By following the correct storage procedures, you can preserve their quality and reliability. Join us in exploring the captivating world of magnetic conductive fiberglass sheets, unlocking endless possibilities in the realm of magnetic applications.

In addition to their magnetic properties, magnetic conductive fiberglass sheets exhibit outstanding mechanical strength. This makes them suitable for demanding applications that require materials to withstand high loads and mechanical stress. From motor components to magnetic wedges, these sheets provide the necessary durability and reliability to ensure optimal performance even in harsh operating conditions.

versatility. They can withstand elevated temperatures without compromising their structural integrity or magnetic properties. This makes them well-suited for applications that involve high temperatures, such as in electric motors or power generation systems. The ability of magnetic conductive fiberglass sheets to maintain their performance under extreme thermal conditions is a testament to their exceptional quality and reliability.

Another advantage of magnetic conductive fiberglass sheets is their lightweight nature. Compared to traditional magnetic materials like iron or steel, these sheets offer a significant weight reduction while maintaining the necessary magnetic properties. This makes them ideal for applications where weight savings are crucial, such as in aerospace or automotive industries. The lightweight properties of these sheets contribute to improved fuel efficiency, enhanced maneuverability, and overall cost savings.

Moreover, magnetic conductive fiberglass sheets can be easily fabricated into various shapes and sizes to meet specific design requirements. Their versatility in manufacturing processes allows for customization, ensuring seamless integration into different applications. Whether it’s complex shapes or intricate designs, these sheets can be tailored to suit the needs of the project, offering flexibility and adaptability.

One significant application of magnetic fiberglass sheets is in the design and construction of transformers. These sheets play a vital role in enhancing the efficiency and performance of transformers by improving magnetic flux distribution. With their high magnetic permeability, they enable better magnetic field conduction, resulting in reduced energy losses and improved overall efficiency. The use of magnetic fiberglass sheets in transformers ensures stable and reliable power transmission, contributing to the smooth functioning of electrical grids.

In addition, magnetic fiberglass sheets find extensive utilization in inductors and magnetic coils. Their ability to channel and control magnetic fields makes them ideal for these applications, where precise magnetic field manipulation is crucial. By utilizing magnetic fiberglass sheets, inductors can achieve higher inductance values and improved overall performance. The use of these sheets in magnetic coils enhances their magnetic coupling efficiency, leading to higher energy transfer and reduced electromagnetic interference.

Moreover, magnetic fiberglass sheets are employed in electromagnetic shielding applications. With their excellent magnetic permeability, they effectively redirect and absorb electromagnetic waves, providing a shield against unwanted interference. This is particularly valuable in sensitive electronic equipment, where electromagnetic compatibility is essential. By incorporating magnetic fiberglass sheets into the design, these shielding solutions ensure reliable operation and prevent data corruption or signal degradation.

Another notable application of magnetic fiberglass sheets is in magnetic sensors and actuators. These sheets are used as core material in magnetic sensors, enabling accurate detection and measurement of magnetic fields. In actuators, they facilitate precise control and movement based on magnetic stimulation. The high magnetic permeability of these sheets enhances the sensitivity and responsiveness of these devices, making them crucial in various industrial and automotive applications.

Furthermore, magnetic fiberglass sheets are utilized in the manufacturing of magnetic wedges for electric motors. These wedges play a significant role in improving motor performance by reducing magnetic losses and enhancing magnetic field distribution. By incorporating magnetic fiberglass sheets as core material in the wedges, motors exhibit improved efficiency, reduced noise, and enhanced overall reliability.

The enchanting features of magnetic conductive fiberglass sheets make them an indispensable material in various industries. With their high magnetic permeability, excellent mechanical properties, and longevity, these sheets have revolutionized the manufacturing of magnetic wedges for motors. By following the correct storage procedures, you can preserve their quality and reliability. Join us in exploring the captivating world of magnetic conductive fiberglass sheets, unlocking endless possibilities in the realm of magnetic applications.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……