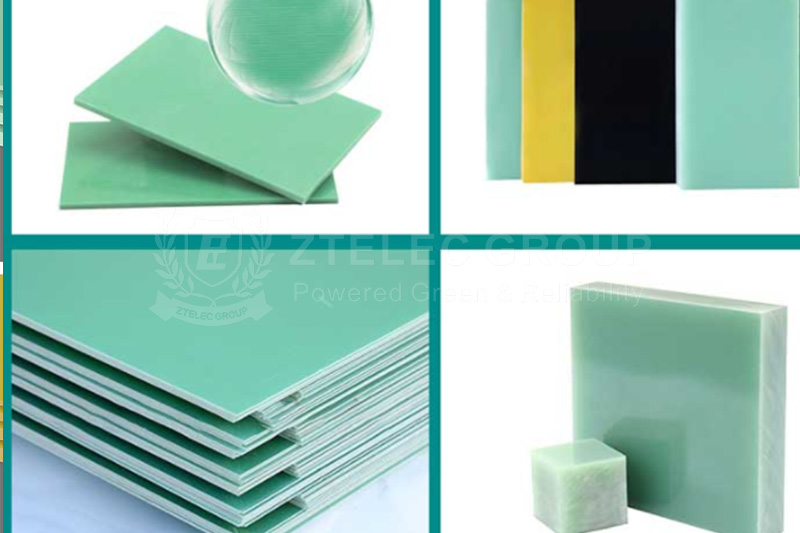

When we use mobile phones, computers, or come into contact with various industrial equipment, we rarely pay attention to the boards that work silently inside. However, it is the seemingly ordinary materials such as FR4 sheet, glass fiber sheet and epoxy sheet that constitute the cornerstone of electronics and industrial manufacturing. They have their own characteristics and play a key role in different scenarios. What are the differences between these three materials? Let’s reveal it to you next.

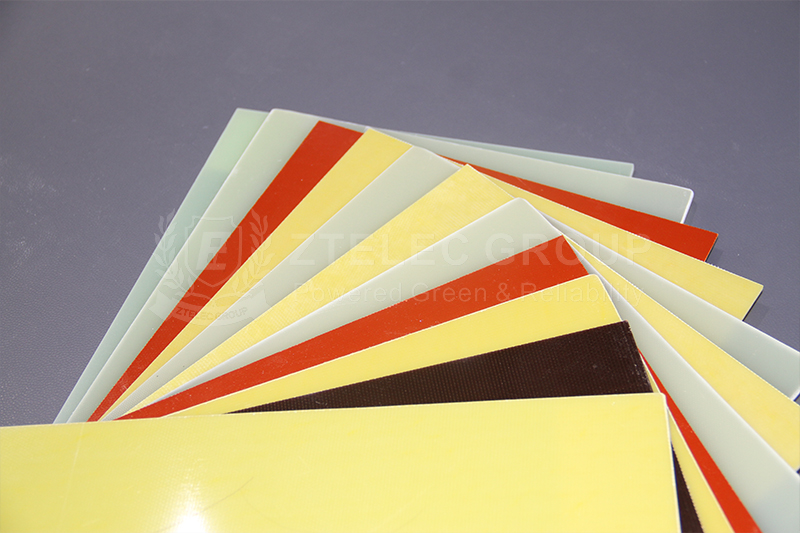

FR4 sheet uses glass fiber cloth as the base material and epoxy resin as the adhesive, and its flame retardancy reaches high safety standards. Glass fiber cloth makes it have high mechanical strength, anti-bending and impact resistance. FR4 sheet has good high temperature resistance and is available in different grades. It has stable electrical properties and is suitable for high-frequency circuits. Therefore, it is often used to manufacture PCB circuit boards, insulation layers of electrical equipment, and is also a common material for industrial control cabinet structural parts.

The base material of fiberglass sheet is glass fiber yarn or felt, and there are many types of adhesives, such as epoxy, phenolic, polyester resin, etc. It has high strength, light weight, excellent tensile strength, but is relatively brittle. It has a wide temperature resistance range. For example, fiberglass sheets made of phenolic resin can withstand high temperatures. However, its electrical properties are greatly affected by the resin and its stability is not as good as that of FR4 sheets. There are many types of fiberglass sheets, covering insulation, heat insulation, structural reinforcement and other types. It is mainly used for thermal insulation of motors and transformers, mechanical structures such as drone frames and ship partitions.

Epoxy sheet has various substrates, such as paper, cotton cloth, and glass fiber, and the adhesive is fixed to epoxy resin. This is different from the fixed reinforcement material of FR4 sheet. It is easy to drill and cut, and it is convenient to customize the shape. The characteristics of epoxy resin make it acid, alkali and moisture-proof. However, the electrical performance is moderate, and the mechanical strength is not high without glass fiber reinforcement. In practical applications, epoxy sheets can be seen in low-voltage insulation gaskets, mold substrates, and anti-corrosion linings of chemical equipment.

Applicable scenarios: If high-precision, high-temperature resistant or high-frequency applications are required, such as electronics, medical equipment and other fields, FR4 sheet is an ideal choice.

Notes: Pay attention to key indicators such as flame retardant grade, dielectric properties and thermal stability of the board to ensure that product requirements are met.

Applicable scenarios: In the fields of transportation, new energy, etc., fiberglass sheet can be used when there are high requirements for the mechanical properties and environmental resistance of the material.

Notes: Select the appropriate type of fiberglass sheet according to the specific application scenario to ensure that its performance meets the requirements.

Applicable scenarios: If the budget is limited and only basic insulation and mechanical strength are required, such as ordinary industrial parts, you can choose general epoxy sheet (such as 3240); if there are high requirements for electrical performance, heat resistance and processing performance, you can choose high-performance epoxy sheet such as FR4.

Note: Pay attention to the heat resistance level, electrical performance and processing performance of the board, and choose products that meet the product requirements.

From the precision circuits of electronic devices to the sturdy structures of large industrial equipment, FR4 sheets, fiberglass sheets, and epoxy sheets are driving the development of the industry with their unique performance. The next time you encounter related products or equipment, you may have a better understanding of these materials. Remember, only by choosing the right board according to actual needs can each material be used to its maximum value.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……