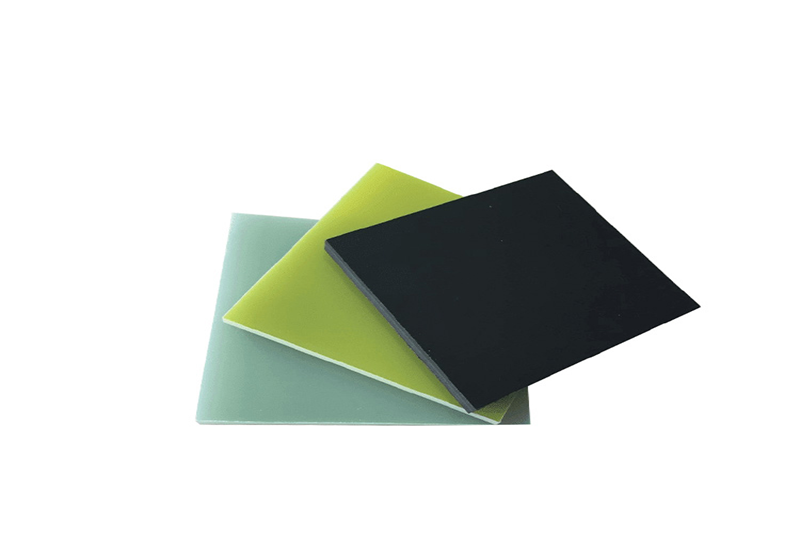

G10 is a composite material made of glass fiber and resin. It is a high-strength B-grade rigid insulating material with an HB flame retardant rating. G-10 is the toughest glass fiber resin laminate, making it very commonly used.

1.High strength: G10 epoxy sheet has excellent strength characteristics, with high tensile and flexural strength. This allows G10 to perform well under heavy loads and high-stress environments.

2.Lightweight: Despite its excellent strength, G10 epoxy sheet has a relatively low density, making it lighter in weight compared to metal materials. This makes it an ideal choice in many applications, reducing structural load and improving efficiency.

3.Good insulation performance: G10 epoxy sheet has excellent insulation properties, effectively isolating currents and preventing short circuits and leakage in electrical equipment. This makes G10 widely used as insulation material and circuit board in the electronic and electrical fields.

4.Corrosion resistance and high temperature resistance: G10 epoxy sheet has good resistance to various chemicals and corrosive media, and can operate stably for a long time in harsh environments. This makes it an ideal choice in chemical, marine, aerospace, automotive engineering, and other environments.

1.G10 has a plastic feel and may not be as attractive as other materials like wood or bone.

2.It can be slippery when wet, making it difficult to grip.

Flame retardant rating: HB.

Density: 1.98-2.08g/cm3.

Water absorption (5mm): ≤0.6%.

Modulus of elasticity: 24000MPa.

Bending strength (normal to layer): ≥340Mpa.

Bending strength (150±2℃): ≥340Mpa.

Impact strength (parallel to layer): 66.7KJ/m².

Impact strength (normal to layer): 45.3KJ/m².

Insulation resistance after immersion (D-24/23): ≥5.0×10²Ω.

Dielectric strength (normal to layer): ≥10.7MV/m.

Breakdown voltage (parallel to layer): ≥40KV.

Relative dielectric constant (1MHz): ≤5.5.

Dielectric loss angle: 3.3*10-2.

.png)

G10 material is well-known for its wide range of applications, including:

1.Slot wedges:

G10 material can be used to manufacture slot wedges, which are used to secure and support coils in motors or generators, ensuring their stability and reliability.

2.Terminal boards and tag strips:

G10 material can be used to manufacture terminal boards and tag strips for connecting and labeling wires and cables in electronic devices.

3.High-voltage switches:

G10 material is used in high-voltage switches, providing excellent insulation performance and corrosion resistance to ensure the safe and reliable operation of high-voltage circuits.

4.Planetary gears:

G10 material can be used to manufacture planetary gears, which are used for power transmission and precise motion control.

5.Mechanical parts:

G10 material can be used to manufacture various mechanical parts, such as bearing washers, gaskets, and insulating washers, providing mechanical support and insulation functionality.

6.Bolt insulation:

G10 material can be used to manufacture bolt insulation sleeves, which are used to isolate and protect the electrical contact between bolts and the surrounding environment.

7.FPC reinforcement plate:

G10 material can be used to manufacture reinforcement plates for flexible printed circuit boards (FPC), enhancing their structural strength and stability.

8.Electronic insulation field:

G10 material can be used as electronic insulation materials, such as insulating gaskets, spacers, and washers, for protecting electronic components and circuits.

9.Transformer spacers:

G10 material can be used to manufacture transformer spacers, which are used to isolate and support windings in transformers, ensuring their normal operation.

10.Electromechanical components and terminal boards:

G10 material can be used to manufacture various electromechanical components and terminal boards for electrical connection, isolation, and protection.

1.Different flame retardant ratings: The biggest difference between G10 epoxy board and FR4 epoxy board lies in their different flame retardant ratings. G10 has an HB flame retardant rating, while FR4 has a V-0 flame retardant rating. Other properties are similar between the two.

2.Price difference: Due to its higher flame retardant rating, G10 is more expensive than FR4.

1.Different glass cloth reinforcement materials:

G10 epoxy board typically uses standard glass cloth reinforcement, known for its excellent electrical insulation properties, mechanical strength, and dimensional stability.

G11 epoxy board, also known as FR5 epoxy board, uses a higher-grade glass cloth (known as E-glass) reinforcement. This alkali-free glass cloth has improved mechanical strength, heat resistance, and flame retardancy compared to thestandard glass cloth used in G10.

2.Higher temperature resistance:

G11 epoxy board has a higher temperature resistance compared to G10. G11 can withstand higher continuous operating temperatures without losing its mechanical and electrical properties.

3.Higher mechanical strength:

G11 epoxy board has higher mechanical strength compared to G10. This makes G11 more suitable for applications that require higher strength and load-bearing capabilities.

4.Higher flame retardant rating:

G11 epoxy board typically has a V-0 flame retardant rating, which is higher than the HB flame retardant rating of G10. This makes G11 more suitable for applications that require higher fire resistance and safety standards.

Overall, G11 epoxy board is a higher-grade material compared to G10, with improved mechanical strength, heat resistance, flame retardancy, and electrical insulation properties. However, G10 is still widely used and offers excellent performance in many applications.

1.Will G10 melt?

G-10 and FR-4 have a rated continuous operating temperature of 140 degrees Celsius (284 degrees Fahrenheit). As thermosetting materials, these grades will not melt; however, prolonged exposure to temperatures above the rated temperature may result in charring.

2.Why is it called G10?

G-10 is a thermosetting industrial laminate made of glass cloth material and epoxy resin. The “G” stands for glass and the “10” represents the specific properties of this type of glass epoxy resin.

3.Is G10 waterproof?

G10 is highly resistant to water and can be considered waterproof. However, due to the materials used and the structure of the handle, it is not completely waterproof. The water permeability is extremely low.

4.Is G10 as strong as aluminum?

G-10 offers a significant advantage in terms of lightweight packaging, helping to reduce the weight of the knife. It has been reported to have the same tensile strength as aluminum, but is 30% lighter in weight.

Our company https://www.ztelecinsul.com, has a large inventory of G10. For more information about G10, please click on the product link. Feel free to call or email us to see if we can assist you with your inquiry.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……