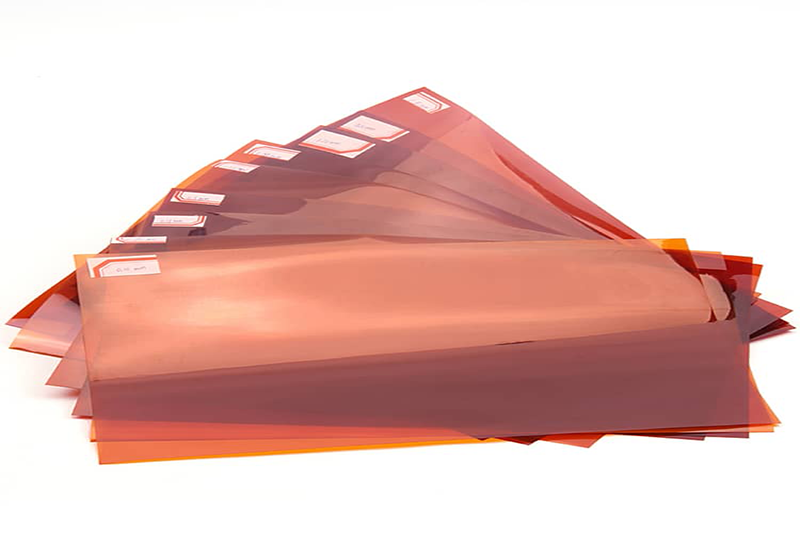

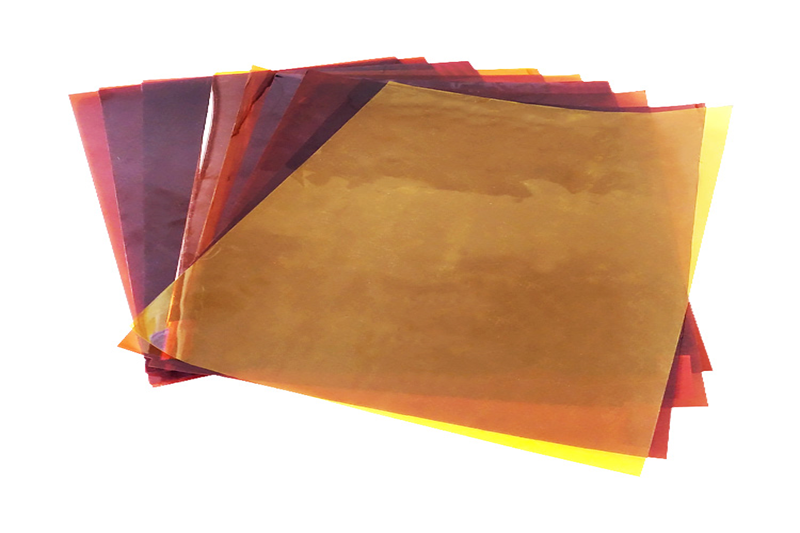

Polyimide film, also known as Kapton film. The tape is based on a polyimide film, and is coated on one side with a high-performance silicone pressure-sensitive adhesive. High-precision coating of ± 2.5um, no scratches, wire drawing, etc., good shear, easy die-cutting processing, excellent high temperature resistance and solvent resistance

Polyimide film is produced by first forming a film from a polyamide acid solution and then undergoing high-temperature imidization. The resulting film is transparent and yellow in color, with a relative density of 1.39 to 1.45.

The surface of the film should be smooth and free from wrinkles, tears, particles, bubbles, pinholes, or any foreign impurities. The edges should be neat and undamaged. Polyimide film is supplied in roll form.

Polyimide film possesses high temperature resistance, radiation resistance, chemical corrosion resistance, and electrical insulation properties, making it suitable for long-term use in air temperatures of 250-280°C.

Coatings:

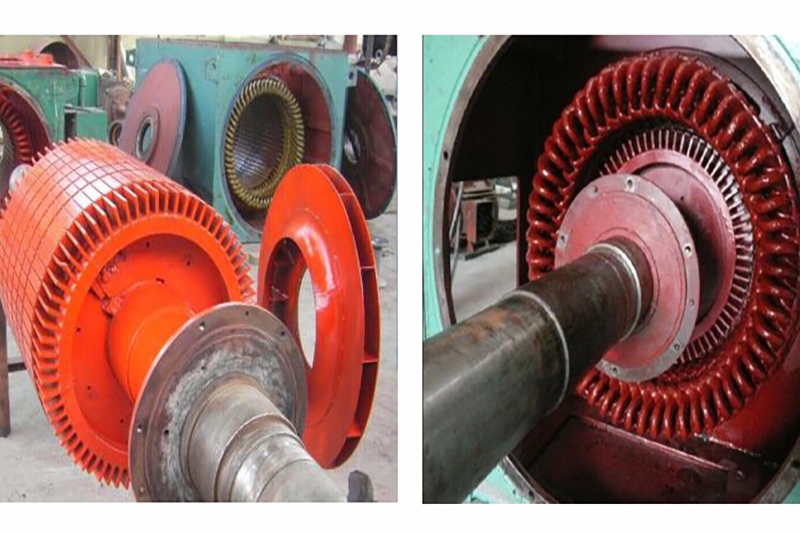

Used as insulation varnish for electromagnetic wires or as a high-temperature resistant coating.

Advanced composites:

Applied in aerospace, aviation, and rocket components. For instance, in the design of supersonic aircraft with a speed of 2.4M, operating at a surface temperature of 177°C and requiring a lifespan of 60,000 hours, approximately 50% of the structural materials consist of carbon fiber reinforced composites with a thermoplastic polyimide resin matrix, totaling around 30 tons per aircraft.

Fibers:

Exhibiting an elastic modulus second only to carbon fiber, it is used in high-temperature media, radiation material filtration, bulletproof and fire-resistant fabrics. Various polyimide products are manufactured in Changchun, China.

Foam plastics:

Utilized as high-temperature insulation materials.

Engineering plastics:

Available in both thermosetting and thermoplastic forms, polyimide can be molded by compression, injection, or transfer molding.

Separation membranes:

Employed for various gas separations such as hydrogen/nitrogen, nitrogen/oxygen, carbon dioxide/nitrogen, or methane, as well as the removal of water from air hydrocarbon feedstocks and alcohols. It also serves as pervaporation or ultrafiltration membranes. Given its heat resistance and resistance to organic solvents, polyimide has significant importance in separating organic gases and liquids.

Photoresists:

Some types of polyimide can be used as photoresists, both positive and negative, with resolutions reaching the submicron level. When combined with pigments or dyes, they can be used for color filter films, simplifying the manufacturing process.

Applications in microelectronic devices:

Used as a dielectric layer for interlayer insulation, as a buffer layer to reduce stress and improve yield, and as a protective layer to minimize environmental impact on devices. Polyimide’s high temperature and chemical stability act as barriers between metal layers and various external environments.

Liquid crystal display (LCD) alignment agents:

Polyimide plays an important role as an alignment material in TN-LCDs, SHN-LCDs, TFT-LCDs, and future ferroelectric liquid crystal displays.

Electro-optic materials:

Utilized as passive or active waveguide materials, optical switch materials, etc. Fluorinated polyimide is transparent within the communication wavelength range, and using polyimide as the matrix for chromophores improves material stability.

Moisture-sensitive materials:

By utilizing the linear expansion caused by moisture absorption, polyimide can be used to create humidity sensors.

Polyimide (sometimes abbreviated as PI) is a type of polymer that contains imide functional groups. It falls under the category of high-performance plastics. Due to its high heat resistance, polyimide finds numerous applications where durable organic materials are needed, such as in high-temperature fuel cells, displays, and various military roles.

Based on the information provided above, if you have any requirements or needs regarding the product, please feel free to contact us anytime.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……