In the realm of healthcare, medical devices play a pivotal role in diagnosis, treatment, and patient care. Ensuring the safety and reliability of these devices is of paramount importance. One crucial aspect in the design and manufacturing of medical devices is the utilization of specialized insulation products. This blog post delves into the significance of specialized insulation products for medical devices and their diverse applications.

Medical devices, ranging from imaging equipment to surgical tools, often involve the transmission of electrical signals or power. Insulation products are essential for preventing electrical leakage and protecting patients and healthcare professionals from potential risks. These products provide vital electrical insulation, ensuring the proper functioning and safety of medical devices.

Insulating tapes, such as medical-grade adhesive tapes, are used in medical devices to provide electrical insulation, secure components, and protect against electrical shocks. They are widely employed in cable assemblies, connectors, and other electrical components.

Insulating films, such as polyimide films, are utilized in medical devices for their excellent electrical insulation properties and high-temperature resistance. They are commonly used in flexible circuits, sensors, and other electronic components.

Insulating foams, such as silicone foam, are employed in medical devices to provide thermal and electrical insulation. They are used in applications such as padding, cushioning, and sealing, ensuring the safety and comfort of patients.

Insulating coatings, such as medical-grade silicone coatings, are applied to medical devices to provide electrical insulation and protect against moisture and chemicals. They are commonly used in electronic components, implants, and surgical tools.

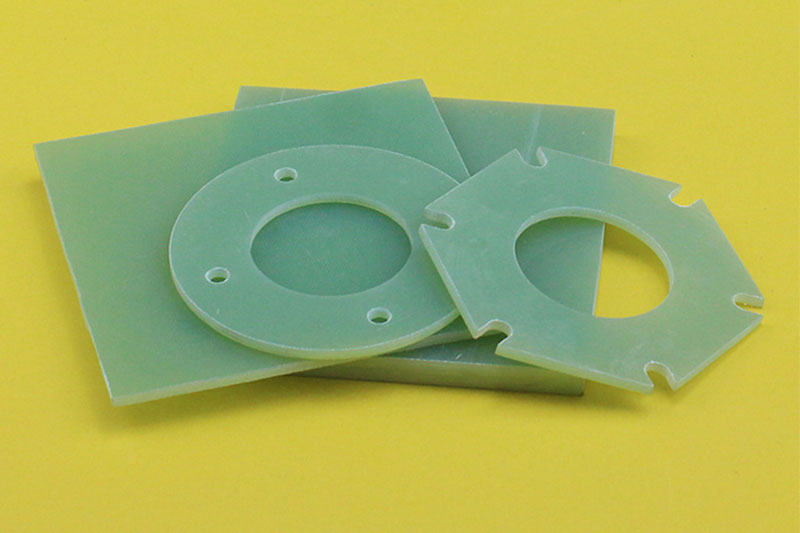

Insulating gaskets and seals, made from materials such as rubber or silicone, are used to provide electrical insulation and prevent leakage in medical devices. They are utilized in applications such as connectors, valves, and pumps.

Specialized insulation products are crucial for electrical components in medical devices, including cables, connectors, and circuit boards. These products ensure safe and reliable transmission of electrical signals or power.

Insulating coatings and materials are utilized in implants and prosthetics to provide electrical insulation and protect surrounding tissues. They ensure the longevity and functionality of these devices.

Insulation products are employed in diagnostic equipment such as ultrasound machines, X-ray devices, and magnetic resonance imaging (MRI) scanners. They provide electrical insulation and protection against interference, ensuring accurate and reliable diagnostic results.

Specialized insulation products are used in surgical tools and equipment to provide electrical insulation, protect against electrical shocks, and ensure the safety of both patients and healthcare professionals.

Specialized insulation products play a vital role in the medical device industry, ensuring the safety, reliability, and performance of healthcare equipment. Insulating tapes, films, foams, coatings, gaskets, and seals are widely used for their excellent electrical insulation properties and compatibility with medical applications. These products are employed in electrical components, implants, diagnostic equipment, and surgical tools, providing electrical insulation and maintaining device integrity. By incorporating specialized insulation products, medical device manufacturers can enhance the overall quality and safety of their products, ultimately benefiting healthcare professionals and patients alike.

If you need our products please write down any questions, we will reply as soon as possible.

There are three ISO certificates for quality certification. The certificates will be shown later. ISO

After receiving the advance payment, the production cycle is 15-25 days. And the transportation cycle should be calcul……

We supply with installation guide and user manual for each transformer. If you do not understand them. We will offer v……