-

+8618695867837 -

+8618695867837

| Name | Parameters |

|---|---|

| Color | Green/Water Green/White/Yellow/Black |

| Thickness | 0.1-100mm |

| Size | 1020*1220 /1020*1020 /1220*2440 /1220*2040 (support customize) |

| Heat Resistance Rating | Class F (150 ° C) |

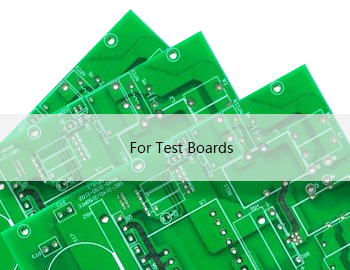

For Test Boards

For Molds

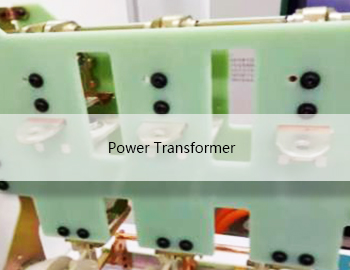

For Power Transformer

For Epoxy Star Wheel

Motor Insulation Materials

PCB Drilling Reinforcement Board

| Parameter | |||||||||||||

| Chinese Name | 3240 | 3241 | |||||||||||

| IEC | EPGC201 | EPGC202 | EPGC203 | EPGC204 | EPGC306 | EPGC308 | -- | ||||||

| NEMA | -- | FR4 | G10 | FR5 | G11 | -- | -- | ||||||

| Basic material | Glass fiber cloth | Electronic grade glss fiber cloth | Glass fiber cloth | ||||||||||

| Resin | Epoxy | Heat resistant epxoy resin | Epoxy | ||||||||||

| Color | NatureGreen | NatureGreen | Black | ||||||||||

| Test item | Unit | Value | Value | ||||||||||

| Density | g/m³ | 1.8~1.95 | 1.75~1.90 | ||||||||||

| Vertical layer bending strength (normal) | MPa | ≥340 | ≥300 | ||||||||||

| Parallel layer impact strength (simply supported beam method) | KJ/m2 | ≥38 | ≥50 | ||||||||||

| Vertical layer electrical strength (90°Ctransformer oil) | Kv/mm | ≥14.2 | ≥8.0 | ||||||||||

| Parallel layer breakdown voltage (90°Ctransformer oil) | Kv | ≥35 | ≥35 | ≥40 | ≥35 | ≥40 | ≥35 | ≥35 | |||||

| Dielectric constant (50Hz) | -- | ≥5.5 | ≥5.5 | ||||||||||

| Dielectric loss factor (50Hz) | -- | ≤0.04 | ≤0.03 | ||||||||||

| Insulation resisitance after immersion | Ω | ≥5.0*1010 | ≥1.0*108 | ||||||||||

| Proof tracking index(PTI) | -- | -- | -- | -- | ≥200 | -- | -- | ||||||

| Combustibility | -- | v-0 | -- | v-0 | -- | -- | HB40 | ||||||

| Temperature index | -- | 130 | 130 | 155 | 155 | 155 | 180 | 180 | |||||

| Water absorption (1-20mm thickness) | mg | 17~73 | 64~193 | ||||||||||

| Notes: The data in the above table only represents typical or average data, just for reference in practical application. It does not bear any responsibility for the use of the product or related legal liability | |||||||||||||

Communication brings us closer together.